1100 glazed tile roll forming machine Supplier & Manufacturer

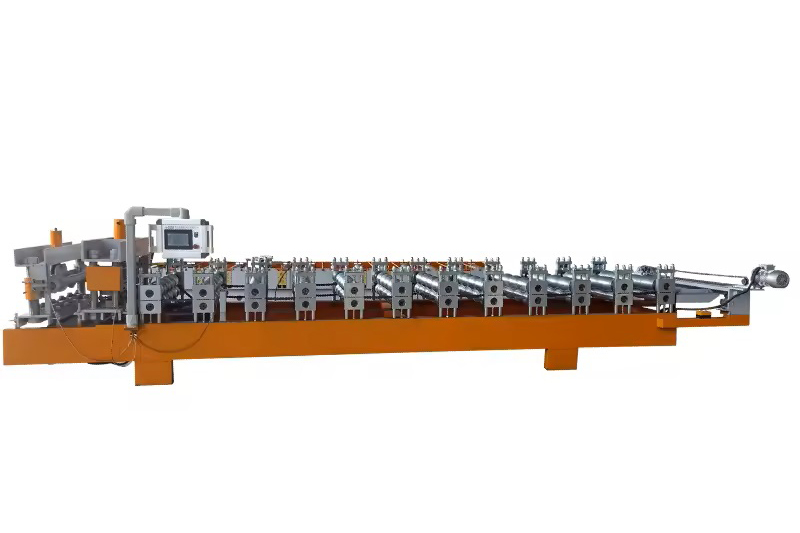

1100 glazed tile roll forming machine

Our company’s glazed tile machine can quickly and accurately process steel plates into glazed tile plates of various specifications. Support customers to customize drawings.

The 1100 glazed tile roll forming machine adopts advanced forming technology and precise control system. With a highly automated production process, it can continuously and stably produce high-quality glazed tile panels, greatly improving production efficiency.

Glazed tiles of antique style or modern design,The glazed tile products produced by this type of tile press machine have the characteristics of beautiful appearance, simple and elegant, rich color and high strength, which are suitable for roof decoration of various buildings, commonly seen in garden factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts and families and other buildings. At the same time, due to the durability of its material and good waterproof performance, it is also suitable for long-term outdoor use environment.

1100 technical parameters of glazed tile forming machine

weight | 5000kg |

dimension | 6.5m* 1.7m* 1.2m |

Color | According to customer demand |

Ingredients | PPGI PPGL GI GL |

thickness | 0.3-0.8MM |

Coil width | According to customer demand |

Apply | Building construction |

Cutting type | Fully automatic hydraulic cutting |

Main frame | 350H steel |

Motor power | 5.5kw |

Hydraulic pump power | 3kw |

productivity | 1.1-1.2M/Min |

Roller material | 45# |

Our 1100 version is mainly 1000mm in width and 28mm in peak height. You can also provide me with the picture of the version you need, and our machine can be customized according to your needs.

Final product sample

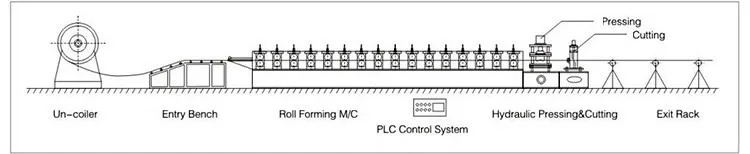

Work flow of glass roof tile pressing machine

Uncoiling — Sheet guiding — Roll forming — Measure length — Pressure pattern — Cutting — Panels to product stand

Apply

- Customized services:Equipment manufacturers support customized services, which can adjust equipment parameters or design according to the specific needs of customers to produce glazed tiles of specific specifications or styles, which enhances the applicability and market competitiveness of products.

- Operation safety:In terms of safety, the equipment design is thoughtful, requiring detailed inspection before use to ensure that the components are firmly connected and lubricated enough, and the power supply needs to be cut off during the installation of molds and other operations to prevent safety accidents, which reflects the importance of the safety of operators.

- Convenient maintenance:It emphasizes the importance of proper maintenance of the equipment before and after use, such as checking the connection, filling the lubricating oil, etc. These measures help to extend the service life of the equipment and keep it in good running condition.