Single layer roll forming machine Supplier & Manufacturer

What is single layer roll forming machine?

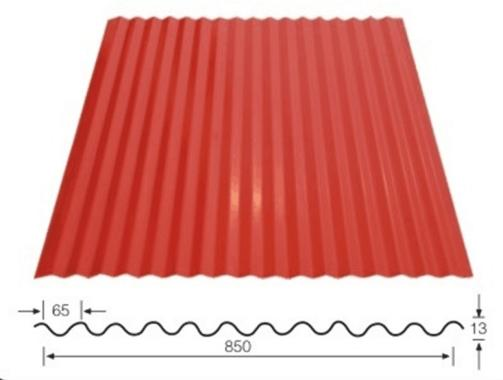

Single-layer color steel tile refers to a laminated steel plate, its size and color can be designed and produced according to customer requirements. Commonly used thicknesses are 0.4mm, 0.5mm, 0.6mm, 0.7mm and 0.8mm. Because of its simple structure and low cost, single-layer color steel tile is widely used in building construction, suitable for light steel structure engineering, factory buildings, warehouses, shopping malls: agricultural markets, etc.

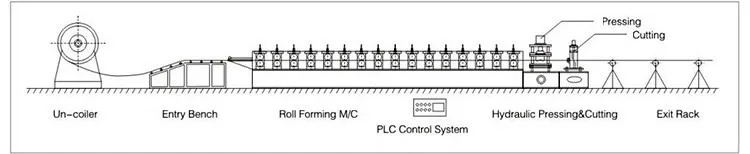

Working flow of single layer forming machine

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

Product Description | |

Name | Galzed floor color coated tile making machine sheet machinery |

Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

Thickness Range | 0.3-0.8 mm |

Coil Width Range | 1000, 1220 or 1250 mm. According to your actual drawing.

|

Cutting type | Automatic Hydraulic Cutting |

Main structure | 350H steel |

Roller material | Cr 12 |

Raw material | PPGI PPGI GI GL |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm.

|

size | 3,11.5*1*1.5m |

Characteristics of single color steel tile former

High Efficiency

It is a kind of high efficiency mechanical equipment, suitable for tile production in industrial production, building tile processing and other fields. Because it has the chara cteristics of high efficiency, high precision and high speed, it can quickly complete various processing tasks and greatly improve production efficiency.

Low Cost

Compared with the traditional manual processing method, the cost of using the tile press is much lower. Because its operation is very simple, only a small amount of human and material resources are required to complete the production task. In addition, the raw material price used by the tile press is relatively low, and the cost is low, which can bring higher profits.

Simple Operation

The operation of the tile press is relatively simple and does not require too much technical experience and expertise. In the case of some simple operations, it only takes about an hour to learn the tile press and immediately produce. This is ideal for beginners and newbies, especially for small businesses.

Fully Functional

The function is very comprehensive, can adapt to different processing needs, can be a variety of shapes, sizes, specifications and other aspects of tile processing. In addition, the tile press supports mass production and can efficiently handle high-volume tile production tasks.

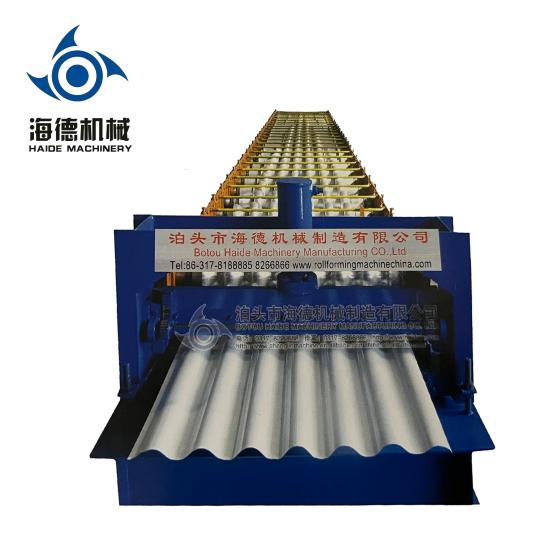

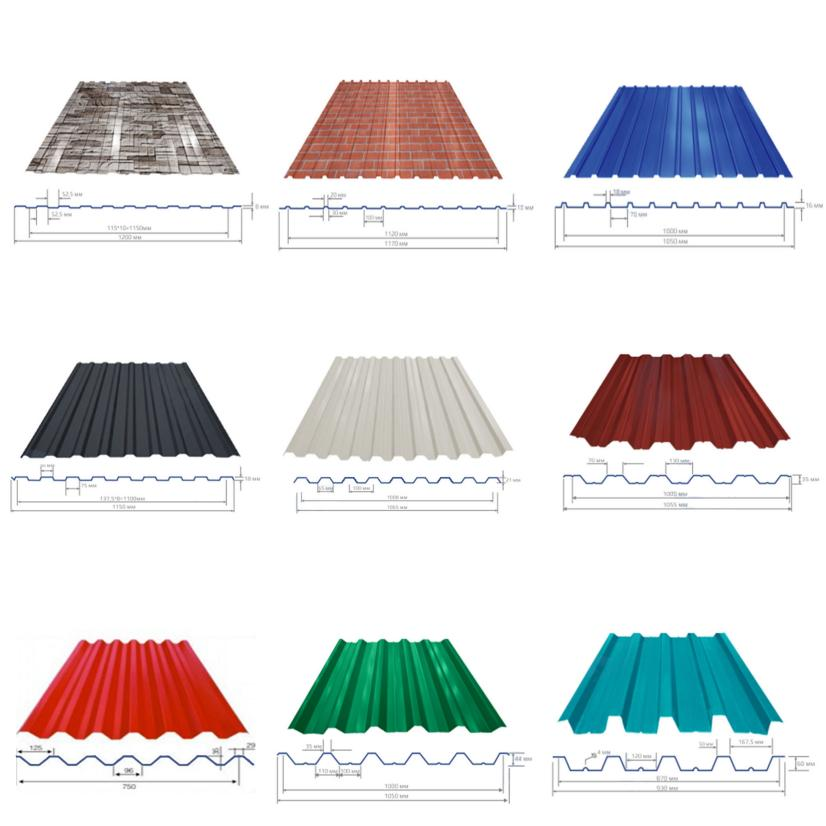

Different models of single layer color steel tile equipment

750 color steel molding equipment

Single board computer can complete many advanced tasks, and has great advantages in processing speed and efficiency.

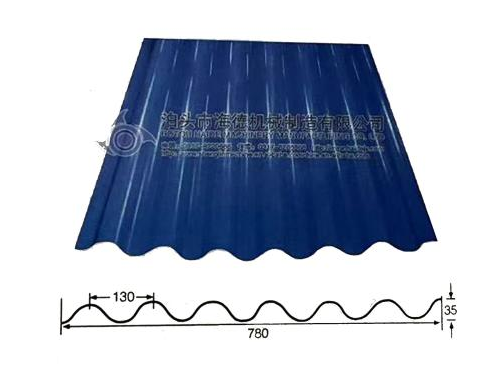

780 steel sheet forming machine

Since many single-board PC brands have official forums and tutorials, beginners can get started quickly and easily.

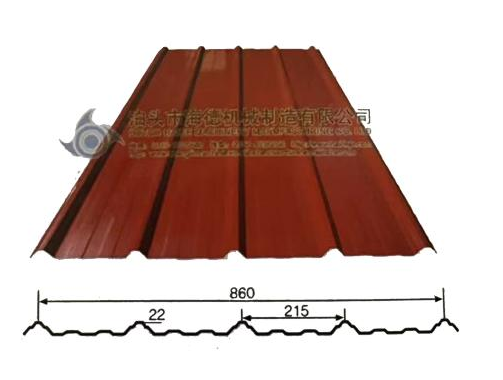

Automatic ibr roof machine

The price is relatively cheap:The price of a single board is low compared to other circuit board types.

900 metal roof panel machine

High production efficiency, good plate quality, long service life

Some different roof color sheet shape diagrams

Factory Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc. Our company produces single-layer color steel tile 750, 780, 840, 900 molding equipment.

FAQ

What is your payment terms?

1.1: We are a 15 years big factory. We have abundant machine designing and making experience. We can give you the best machine solution.

1.2: We have completed production system. And more than 20 sets of CNC machines which can support lots of machine orders’ making and guarantee the delivery.

1.3 : We have 20 years foreign trade exported experience. Our sellers abundant experience can guarantee you will have a pleasant purchase and use of the machine and after-sales experience. And cooperated with us , you can get more details about the machine, including those problems that you can’t think of but we can think of, we can tell you to ensure that you can buy the most suitable machine for you.

1.4 : We are a golden integrity roll forming machine company.

About the after-sale services, no worries, we will responsible for you.

We accept 30% T/T as deposit and 70% T/T as balance before shipping.