Gutter Making Machine Supplier & Manufacturer

What is gutter making machine?

It is a chute and drainage pipe located on the roof, which is used to collect and discharge rainwater to prevent the rainwater from staying on the roof for a long time, causing leakage and deterioration of the house.

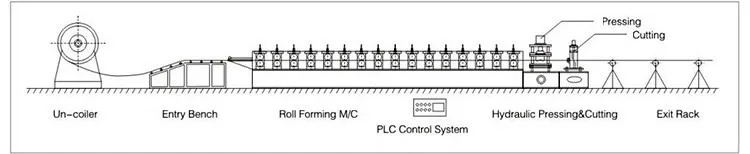

Working Flow of rain gutter making machine

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

Product Description | |

Name | Gutter forming machine |

Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

Thickness Range | 0.3-0.8 mm |

Feed width | 333 450 500mm. According to your actual drawing.

|

Cutting type | Automatic Hydraulic Cutting |

Main structure | 350H steel |

Roller material | Cr 12 |

Raw material | PPGI PPGI GI GL |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm.

|

After-sales Service Provided | Online Support Video Technical Support |

Gutter downspout machine features

Strong corrosion resistance

Good corrosion resistance among them, can it effectively prevent rust And the erosion of the gutters.

Low cost

It’s cheap and easy to produce.The cost is relatively low.

Strong adaptability

The advantages of easy processing; light weight, etc. It can be cut,Bending and other processing press.Different house shapes and tilts angle, but also to meet the needs a different house.

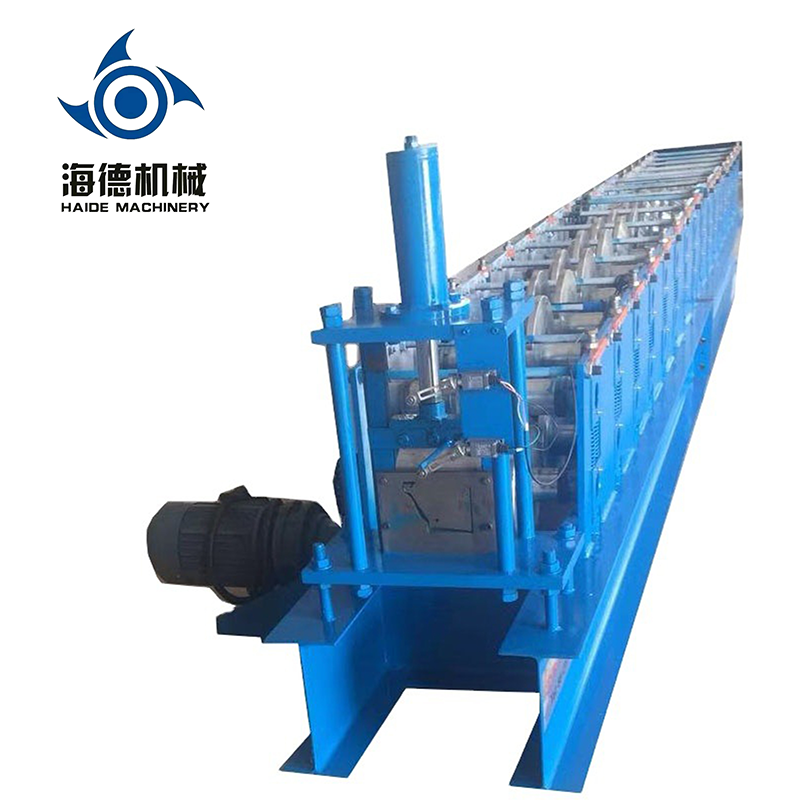

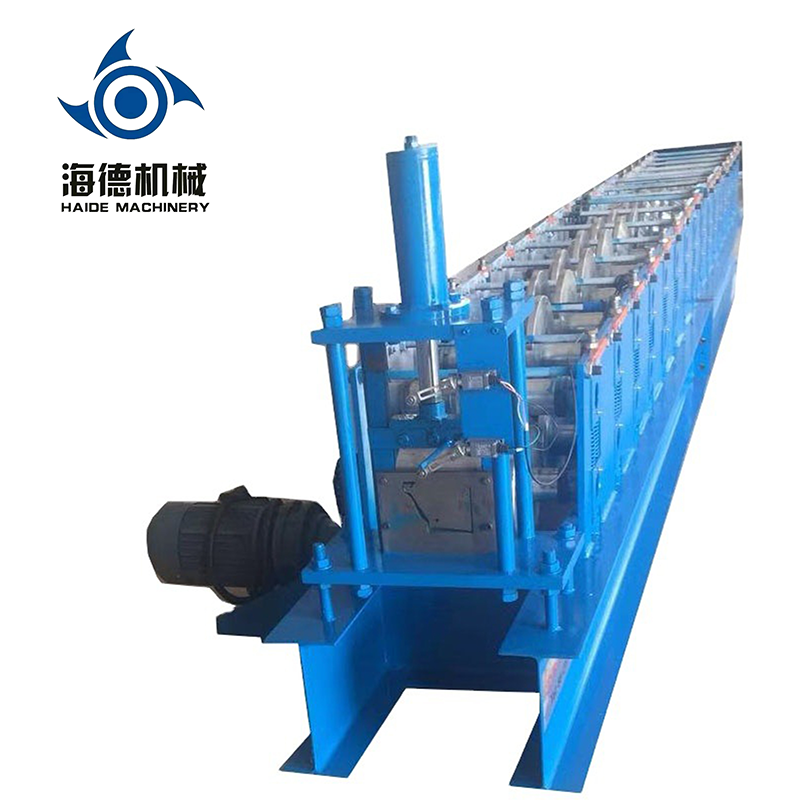

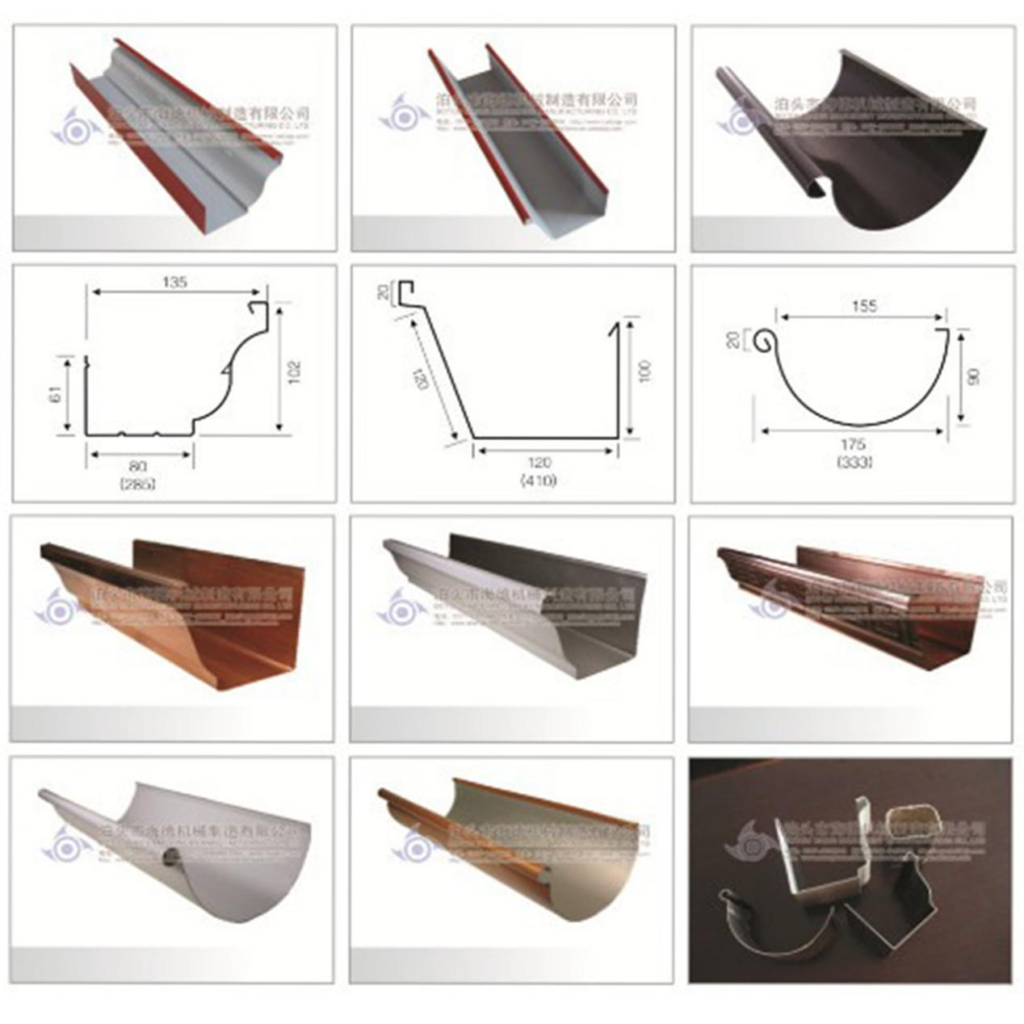

Different type of gutter rolling machine

175 gutter rolling machine

It has the advantages of operation, maintenance, maintenance, mechanical debugging, mold replacement and so on.

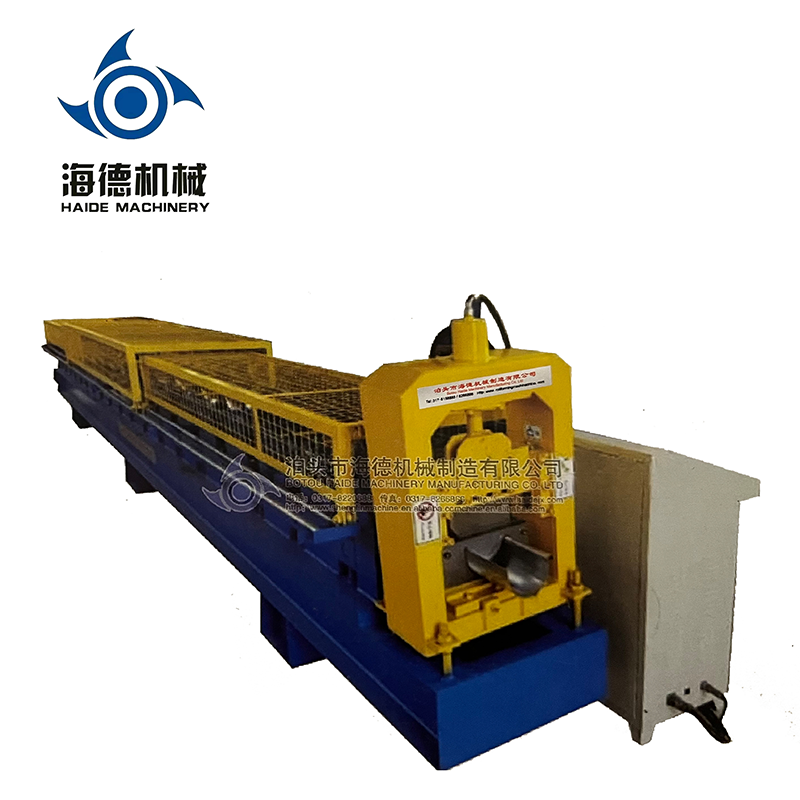

120 gutter roll forming machine

The whole unit automation control system adopts highly integrated network, which makes the automation system performance better.

175 rain gutter roll forming machine

Adopt high level automatic control software to realize production information management.

It increases production Equal emphasis on efficiency and quality, reducing the burden. Production costs are effectively resolved traditional cement tile gutters are easy aging, water leakage and other problems.

Our factory introduce

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc.

FAQ

30% by TT for the advance payment at order

70% will be paid after inspection in China before shipment.

During the warranty period of the machine, we will buy and send you free accessories for non-artificially damaged parts.

24 months from the date of loading by the seller, during the warranty period, we provide lifetime free technical support and repair consultation.