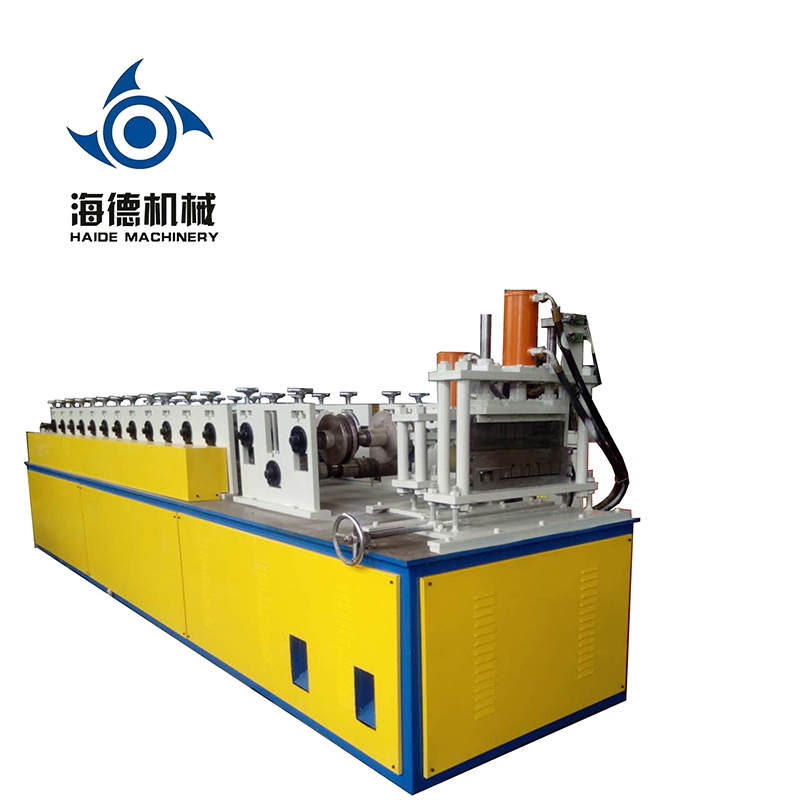

Light steel keel roll forming machine Supplier & Manufacturer

What is light steel keel roll forming machine?

Ceiling roll forming machine, also known as light steel keel machine, is a special machine for processing light steel keel, its main working principle is to process thin steel plates into different shapes of steel keel through pressure and cutting, in order to facilitate the use of construction projects.

Drywall roll forming machine is based on strip steel as raw materials, through continuous cold rolling molding, the production of complex section profiles (products are: light steel keel, paint keel, card keel, various building profiles, steel structure, steel lining door frame profiles, high-speed guard, etc.) and different specifications of cold bending, paint unit equipment, using PLC control.

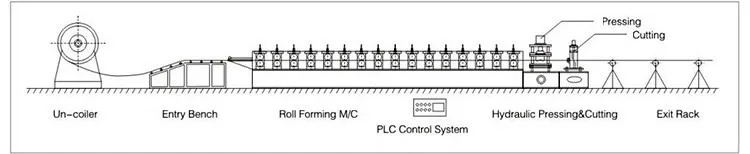

Working Flow light steel keel machine

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

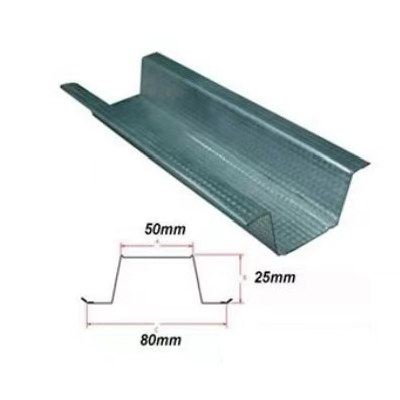

Product Description | |

Applicable material | Cold rolled steel plate, hot rolled steel plate, aluminum plated zinc plate, stainless steel plate and other materials |

Production rate | 30-50m/min |

Transmission mode | It adopts chain drive or gear drive, which has the advantages of stable transmission and low noise. |

Host power | 5.5+4kW, the specific power depends on the equipment size and capacity requirements |

Control system | Usually equipped with PLC control system: can automatically control the production process, to achieve the adjustment and monitoring of production parameters. |

Roller material | Common material/45#/Bearing steel/cr12/cr12mov |

Cutting mode | Using hydraulic cutting or electric cutting, you can cut the shingle to ensure the accuracy of the size of the shingle. |

Overall dimension | 4500mm*750mm*1300mm |

Gross weight | 1500kg |

Roll material thickness | 0.3-0.8mm |

Advantages of keel roll forming machine

1.Higher production efficiency, compared with traditional manual manufacturing and processing, the use of CNC integrated control equipment, processing efficiency is higher, can achieve 24 hours of uninterrupted production, daily production can maintain 4-6 tons /8 hours, to meet the business and production needs of enterprises;

2.Save labor, full CNC production, only need to import the production file into the computer, select the corresponding processing file, equipped with 2 operators can be produced, compared with the traditional need 4-6 talents to meet the needs, save more manpower;

3.Widely used in construction, such as light steel structure buildings, walls, ceilings and other aspects, so the keel machine plays a pivotal role in building construction.

4.With the continuous development of keel, keel machine is gradually applied to home decoration, such as wall lining board production, roof board production.

5.Fully functional, automatic villa keel machine from punching to forming, inkjet, cutting, the entire processing process of a equipment to engage in public keel materials for most of the housing construction.

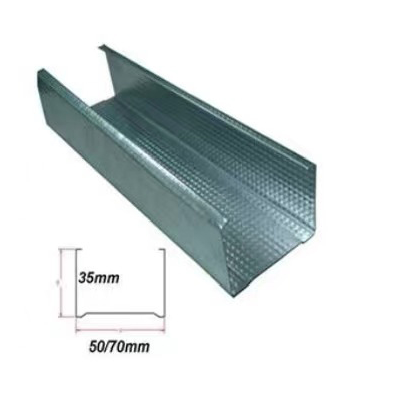

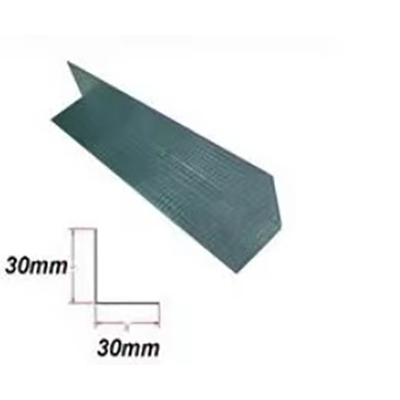

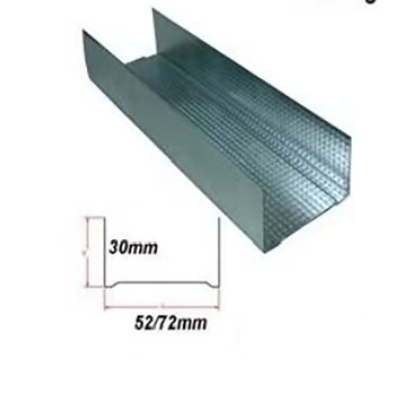

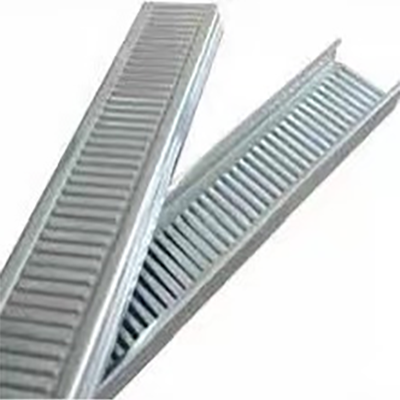

More light keel types

Features of the light keel roll forming machine

Improve the quality of building construction

The keel machine can process the keel into a standard size and shape, improving the quality and efficiency of construction.

Reduce labor costs

Using the keel machine for the processing and production of light steel keel can greatly reduce labor costs and improve operation efficiency

Improve construction safety

To a certain extent, it has enough strength and toughness, which can provide additional security for building construction.

Main Using

Keel machine is mainly used in tunnels, subways, hydropower stations, underground caverns and other I-beams, channel steel bending.

Factory Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc. Our company produces keel forming machine equipment, which are U and C forming equipment, and can also be arbitrarily matched with two types of tile type according to the needs of users.