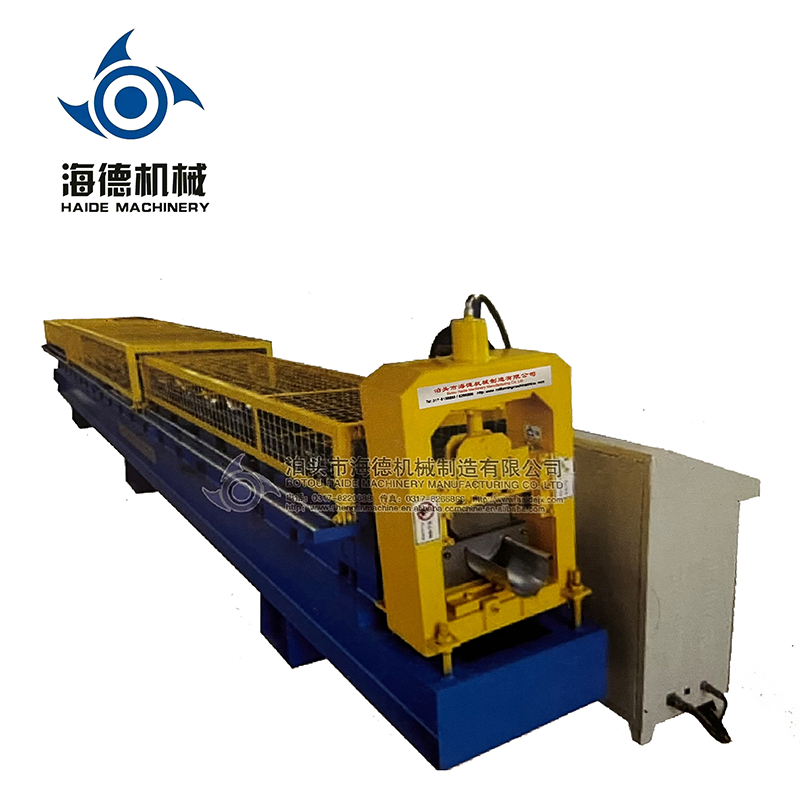

85 Gutter Molding Machine Supplier & Manufacturer

What is 85 gutter making machine?

The main function of the 85 machine is to convert sheet metal into roof tiles through a series of mechanical processes, all carried out with high precision to ensure consistent quality

Gutter press is a kind of mechanical equipment specialized in the production of gutter (drainage system components for construction), usually used to process metal materials, such as galvanized steel, to form a specific shape and specification of gutter. The application of this type of equipment is not limited to specific countries, but is widely used in many countries and regions around the world, as long as there is construction demand in these places, especially industrial or civil construction projects that need to install trenches.

The gutter press is designed and manufactured in accordance with international standards and specifications, so it can serve any country in the world that needs such equipment. Users can choose the right type of gutter tile according to their geographical location, engineering needs and local building material standards, and consider the adaptability of the machine, work efficiency, and customized services. For example, the manufacturer information mentioned includes manufacturers from different parts of China, indicating that these devices are not only circulating in the Chinese market, but also have the conditions to export to other countries.

In short, as a construction machine, its applicability is not limited by the country, and such equipment can be used around the world as long as there is a corresponding market demand.

Application of 85 gutter roll forming machine

The shingles produced by this machine are widely used in residential, commercial buildings, industrial plants, warehouses, gymnasiums

The roof drainage system of various buildings such as exhibition halls meets the needs of different regulations and types of buildings. Because of their aesthetics and durability, they are favored in the construction of residential, commercial buildings, industrial plants and exhibition halls.

How to see if Version 85 is right for you?

Choosing the right gutter molding machine requires consideration of factors such as production capacity, tile profile, material compatibility and budget.

Product Specification

Material loading: The process begins with loading the coil onto the machine. The coil is unwound and fed into a roll forming machine, where it goes through a series of forming processes. Galvanized steel coiling machine, hydraulic coiling machine, electric coiling machine for your choice.

Guide and straightening: The machine includes a guide and straightening device to ensure that the metal coils are properly aligned and straightened before entering the roll forming part. This helps maintain the accuracy and consistency of the molded panel.

Roll forming part: The heart of the machine is the roll forming part, which consists of a series of panel rollers that gradually shape the metal coils into the desired PBR roof panel profile. Each roll forming die performs a specific bending or copying action to gradually transform the flat metal coil into the final panel shape.

Cutting: Once the rolled profile is fully formed, a cutting mechanism is used to cut the rolled profile product to the desired length. This can be done using flying shears or hydraulic shears, depending on the design of the machine.

Stacking or unloading: After the cutting process, the finished PBR roofing panels are automatically stacked or unloaded onto a conveyor belt for further processing or packaging. Stacking devices can be installed in the machine to stack the panels neatly to facilitate the handling and transportation of the rolled sheet metal roof.

Control system: The PBR roof roll forming machine is equipped with a control system that allows the roll forming machine operator to monitor and adjust various parameters. This includes controlling the speed of the PBR machine, adjusting the length of the metal roof and siding, and ensuring that the panel quality is consistent. There are Delta control systems and Siemens control systems for your choice.

The main price of the 85 gutter forming machine for sale

Type of machine | Degree of automation | Price range |

Basic manual | low | $8000-$10,000 |

semi-automatic | middling | $12000-$15,000 |

Fully automatic | high | $17000-$20000 |

There are several factors that affect the cost of a glazed tile forming machine:

Automation: Machines with higher levels of automation are generally more expensive due to the technical and programming complexity required.

Speed and efficiency: Machines that are faster and produce more often cost more.