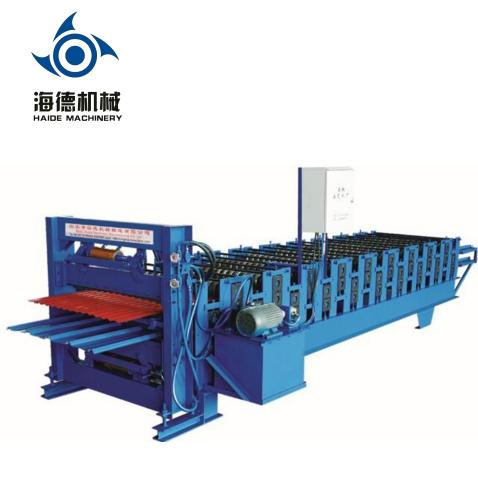

Double Layer Roll Forming Machine Supplier & Manufacturer

What is double layer roll forming machine?

Double layer tile pressing machine is a single layer tile pressing machine modified from several, to achieve a dual-use, easy to operate, reduce costs, automatic production, durable and other characteristics.

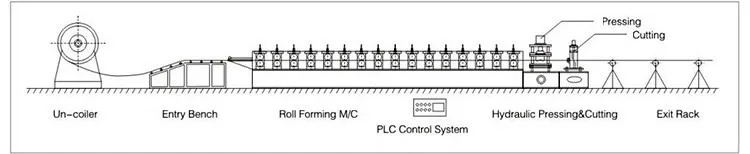

Working Flow

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

The color steel plate produced by the double-layer tile pressing machine has all the characteristics of the color steel plate produced by the single-layer tile pressing machine, with smooth appearance, uniform corrugation, high utilization rate, impact resistance and high strength.

According to the different models, it can be used in steel structure buildings: such as steel structure workshops, warehouses, garages, hangars, stadiums, pavilions, etc.

Double-layer tile pressing machine adopts high-level automatic control software to realize production information management. The whole unit automation control system adopts highly integrated network, which makes the automation system superior performance.

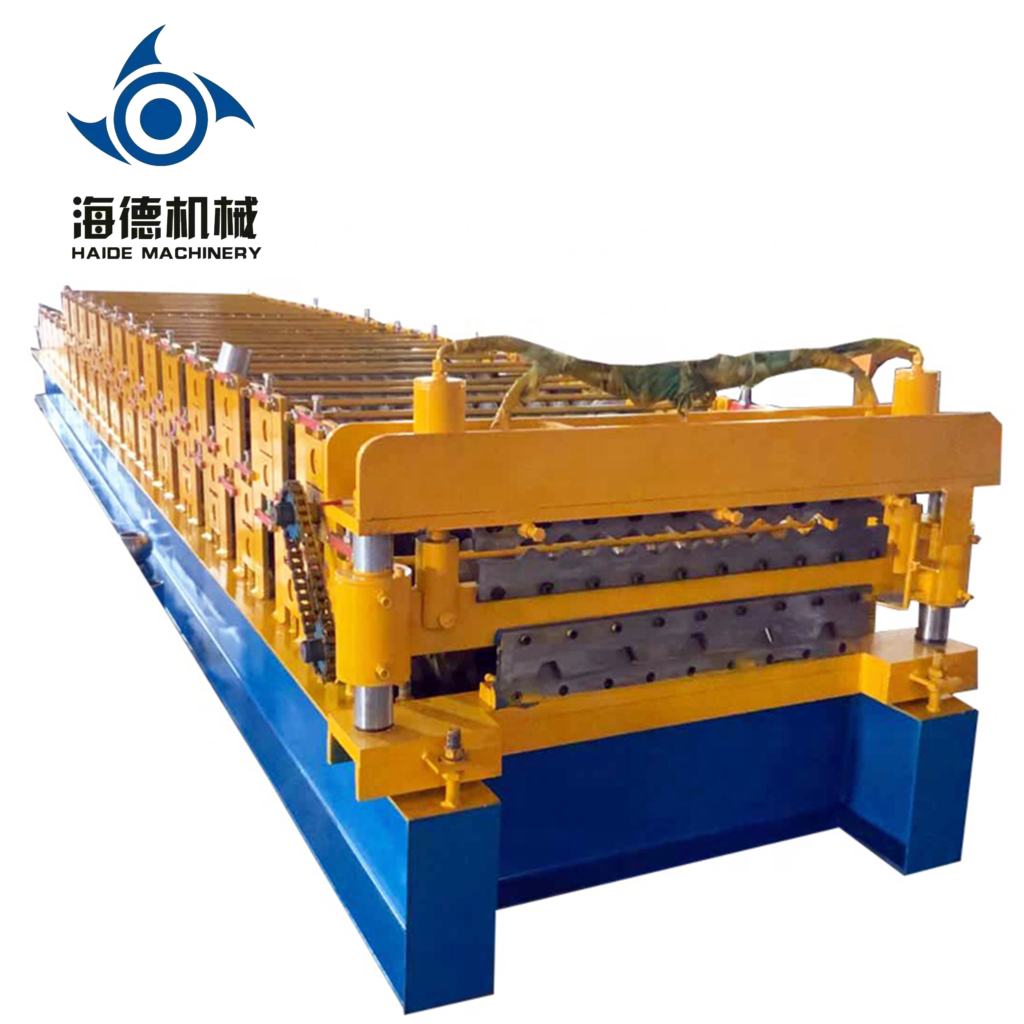

Economical, two types of equipment can be composed of one, that is, the floor space is saved, and the cost of double layer is much lower than that of two single-layer machines.

Product Description | |

Applicable material | Cold rolled steel plate, hot rolled steel plate, aluminum plated zinc plate, stainless steel plate and other materials |

Production rate | 15-20m/min |

Transmission mode | It adopts chain drive or gear drive, which has the advantages of stable transmission and low noise. |

Host power | 5.5-7.5kW, the specific power depends on the equipment size and capacity requirements |

Control system | Usually equipped with PLC control system: can automatically control the production process, to achieve the adjustment and monitoring of production parameters. |

Roller material | Common material/45#/Bearing steel/cr12/cr12mov |

Cutting mode | Using hydraulic cutting or electric cutting, you can cut the shingle to ensure the accuracy of the size of the shingle. |

Overall dimension | 6000mm*1500mm*1700mm |

Gross weight | 5000kg |

Roll material thickness | 0.3-0.8mm |

Gross power | 5.5kw+5.5kw |

Characteristics of double-layer forming machine equipment:

Good comprehensive economic benefits:

Due to the short construction period, it can be put into use in advance and obtain investment benefits in advance. The use of colorful molded steel plate, beautiful and gorgeous, the dynamic sense of the surrounding environment.

Good seismic performance:

Because the steel structure is a flexible structure and its own

weight is light, it can reduce the impact of earthquakes and disasters. China is a multi-earthquake area, steel structure should be vigorously promoted in the construction of earthquake area, which can reduce earthquake disasters and casualties.

Short construction period:

The big advantage of light steel structure is that all components can be made by the factory and assembled on site, which only takes 45 days to 2 months for small industrial plants in general. The use of reinforced concrete structure of the building will take about 6 to 8 months.

Easy to disassemble and relocate:

Once the owner is not satisfied with the selected site or unexpected changes in the external environment, the entire building can be demolished in a very short time with little loss, and all these characteristics are not available in reinforced concrete buildings.

Double layer roll forming machine video

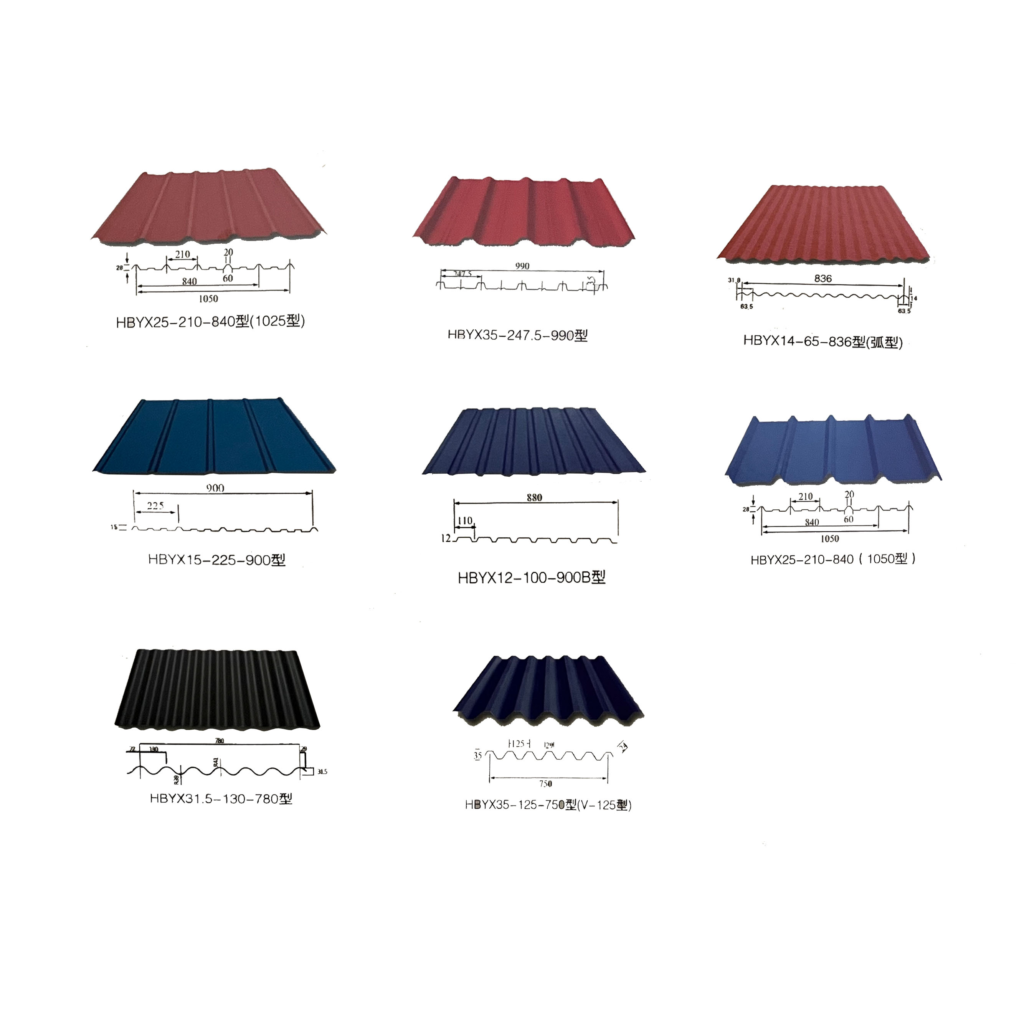

More roof sheet type

Factory Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc. Our company produces double-layer forming machine equipment, there are 840-900, 860-900, 840-910, 850-900 and so on. Can also be according to the needs of users, arbitrary with two types of tile type.