Ridge Cap Roll Forming Machine Supplier & Manufacturer

What is ridge cap roll forming machine?

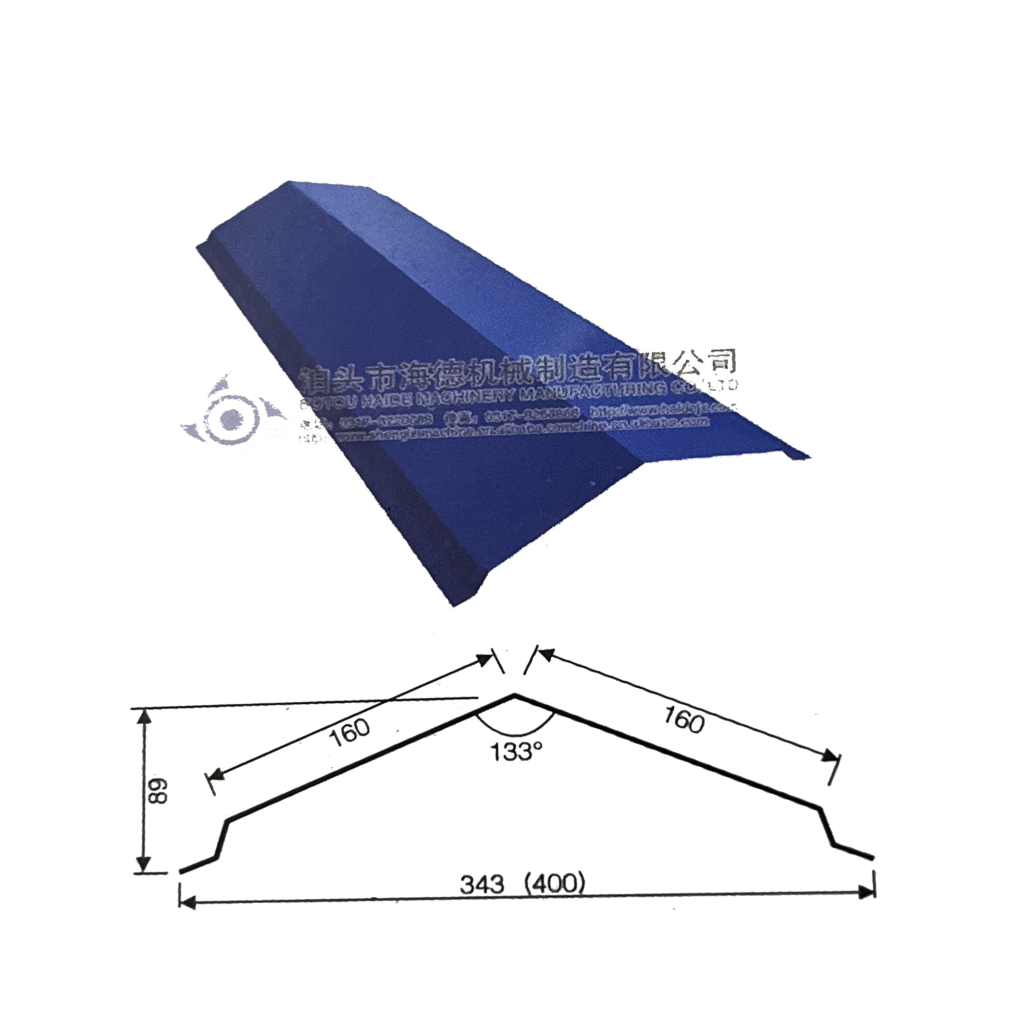

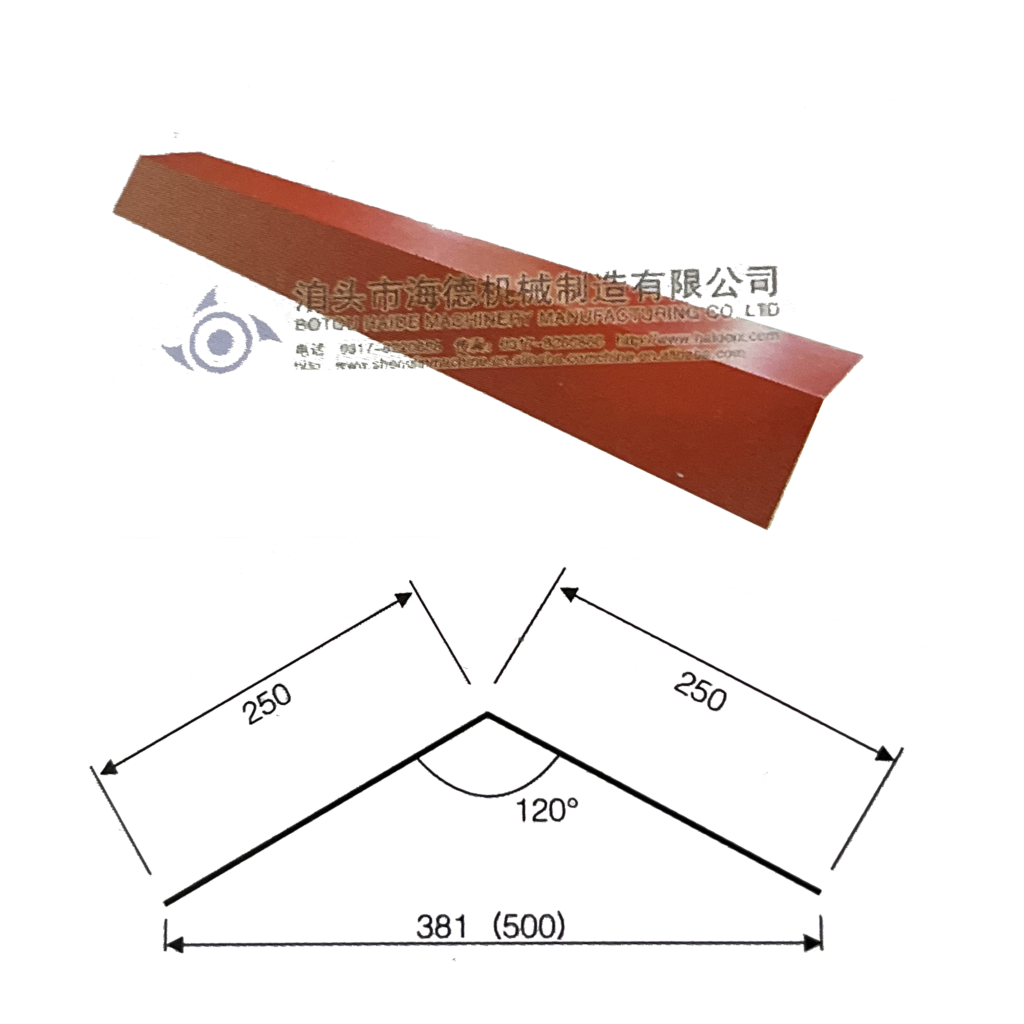

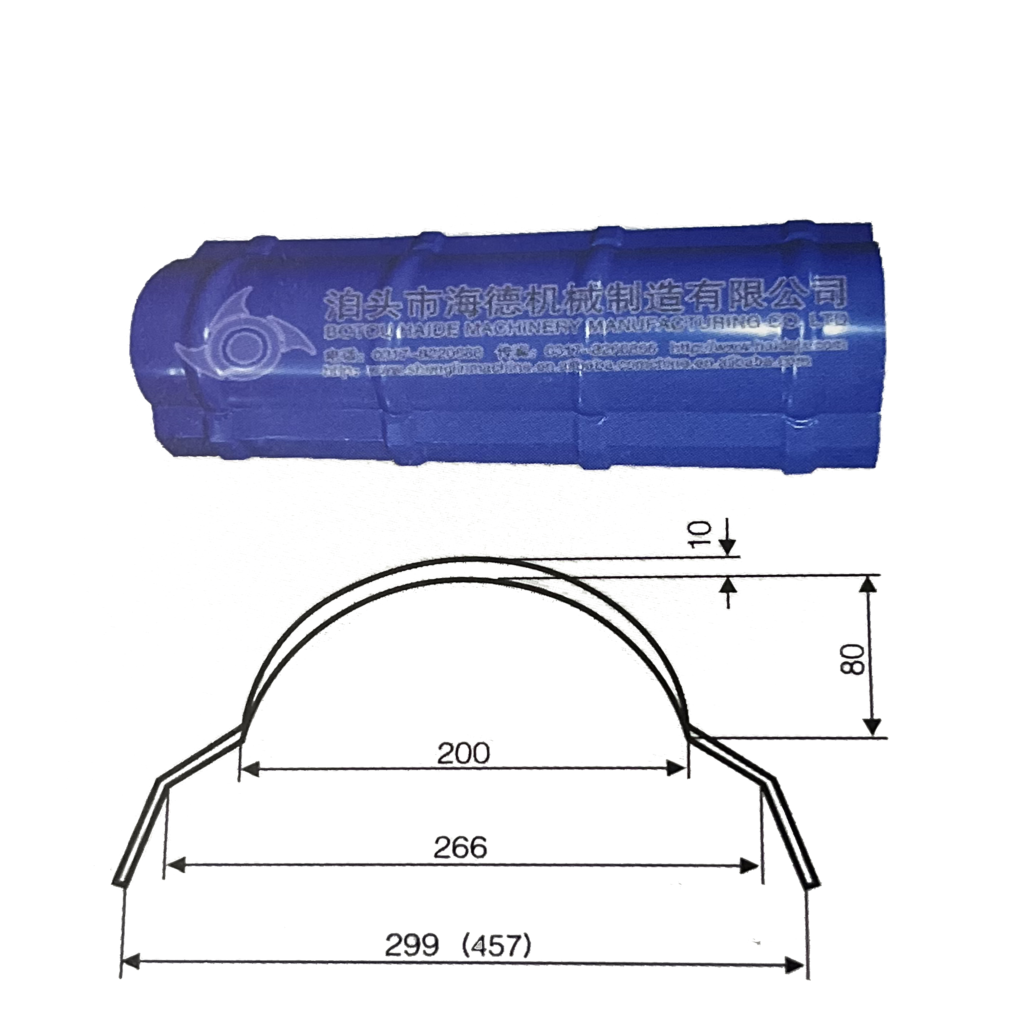

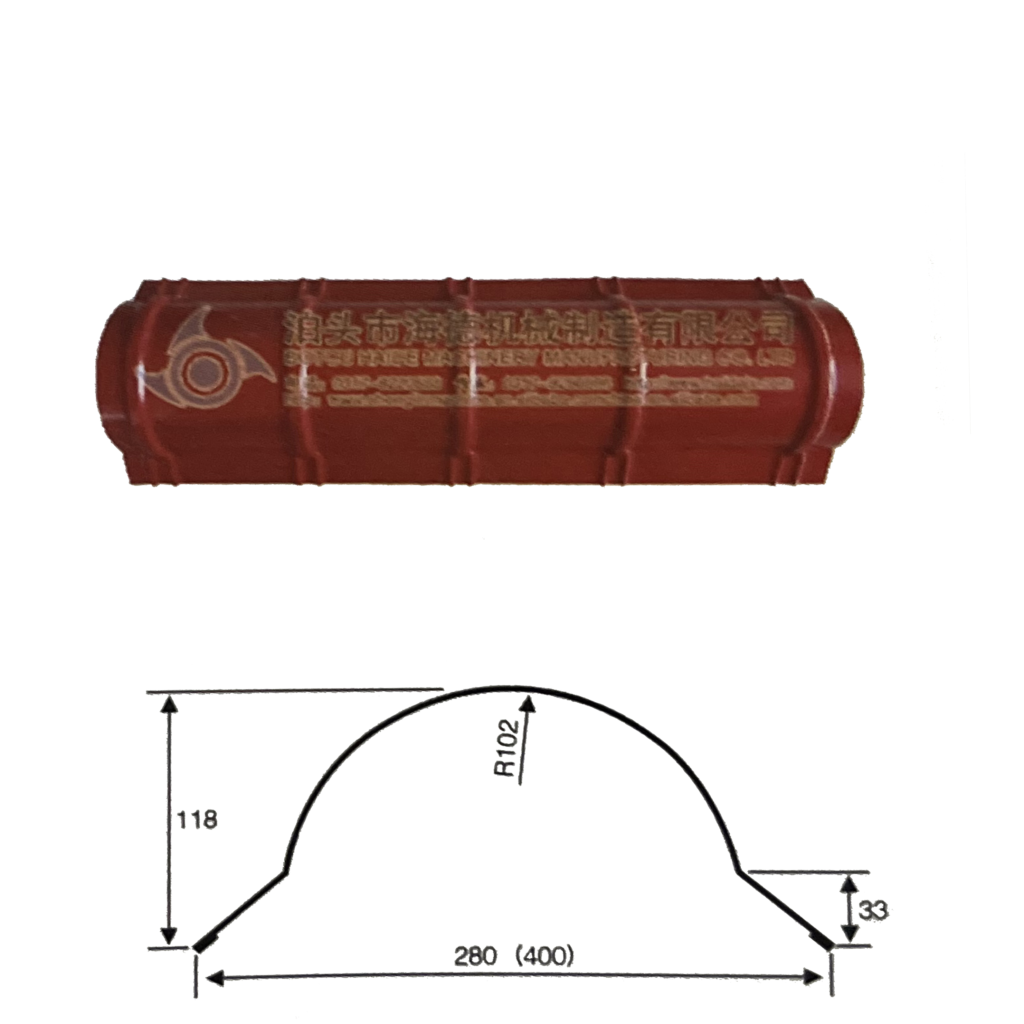

ridge cap machine is mainly used for the production of ridge board, the traditional ridge are with glazed tiles, this type of pressed out products are widely used in new rural construction, flat slope engineering, holiday village and villa building ridge.

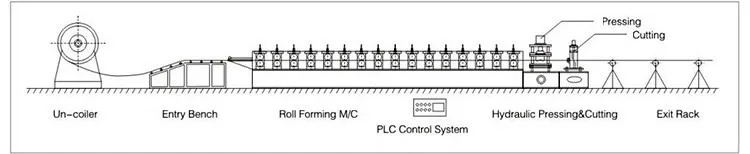

Working Flow

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

Product Description | |

Name | Roof tile forming machine |

Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

Thickness Range | 0.3-0.8 mm |

Feed width | 300 400 500mm. According to your actual drawing.

|

Cutting type | Automatic Hydraulic Cutting |

Main structure | 350H steel |

Roller material | Cr 12 |

Raw material | PPGI PPGI GI GL |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm.

|

size | 6.5m*1.2m*1.2m |

Characteristics of ridge forming machine:

Ridge tile forming machine structure is reasonable, easy to operate, function,feed, pressure drop glue, heating, trimming, grooving, cut sheet.

Adopt low speed metering pump variable frequency speed regulation, (or stepless speed regulation), computer control, accurate measurement.

The whole unit automation control system adopts highly integrated network, which makes the automation system superior performance.

Ridge tile forming machine adopts roll forming technology and hydraulic forming with mold. Products are widely used in construction color steel plateroof connection.

The host adopts programmable controller and touch screen control, the speed is continuously adjustable, and the board type can be customized according to customer requirements. Easy to maintain and debug the machine and change the mold.

flashing roll forming machine is mainly used for the production of ridge board, the traditional ridge are with glazed tiles, this type of pressed out products are widely used in new rural construction, flat slope engineering, holiday village and villa building ridge.

Roof tile color equipment using computer motherboard and relay, inverter, production efficiency can reach 8-12m/ min.

Roofing materials are developing in the direction of light weight, beautiful appearance, environmental protection, sound insulation and so on.

A ridge tile has a structure consisting of a crown that replaces a ridge cushion tile in a past ridge tile, a base part for laying on a corrugated tile, and an outer side part equivalent to a cap ridge tile in a past ridge tile to form an appearance.

Haide Factory Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc.