C Z purlin roll forming machine Supplier & Manufacturer

What is C/Z purlin machine?

CZ purlin machine can produce two different types of purlins, of which the C-type purlin texture is very stable, has a very good compression ability, even if the withstand a very heavy external force, will not affect the flatness of the purlin; Z-type purlins not only have strong pressure resistance, but also can be built and installed in the opposite direction, can adapt to different needs.

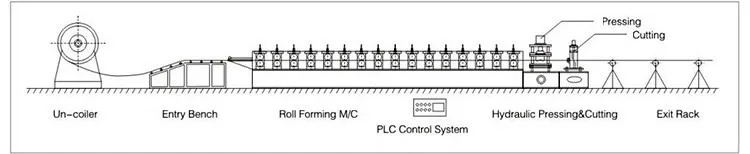

Working flow of cz purlin making machine

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

Product Description | |

Name | C/Z steel purlin forming machine |

Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

Thickness Range | 0.3-0.8 mm |

Feed width | 333 450 500mm. According to your actual drawing.

|

Cutting type | Automatic Hydraulic Cutting |

Main structure | 350H steel |

Roller material | Cr 12 |

Raw material | PPGI PPGI GI GL |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm.

|

After-sales Service Provided | Online Support Video Technical Support |

Features of c and z purlin machine

A new force leading modern architecture

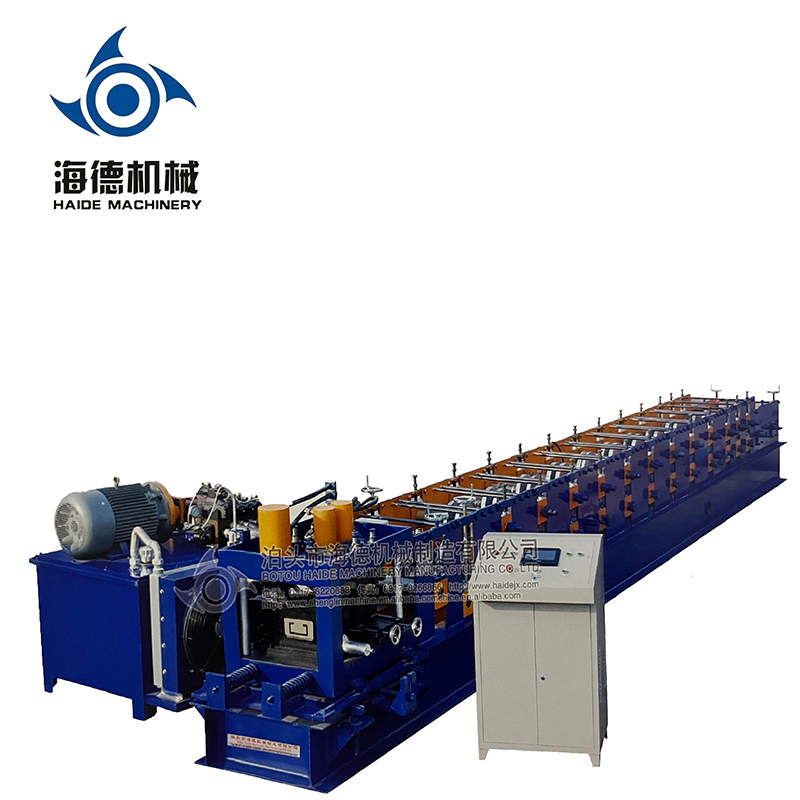

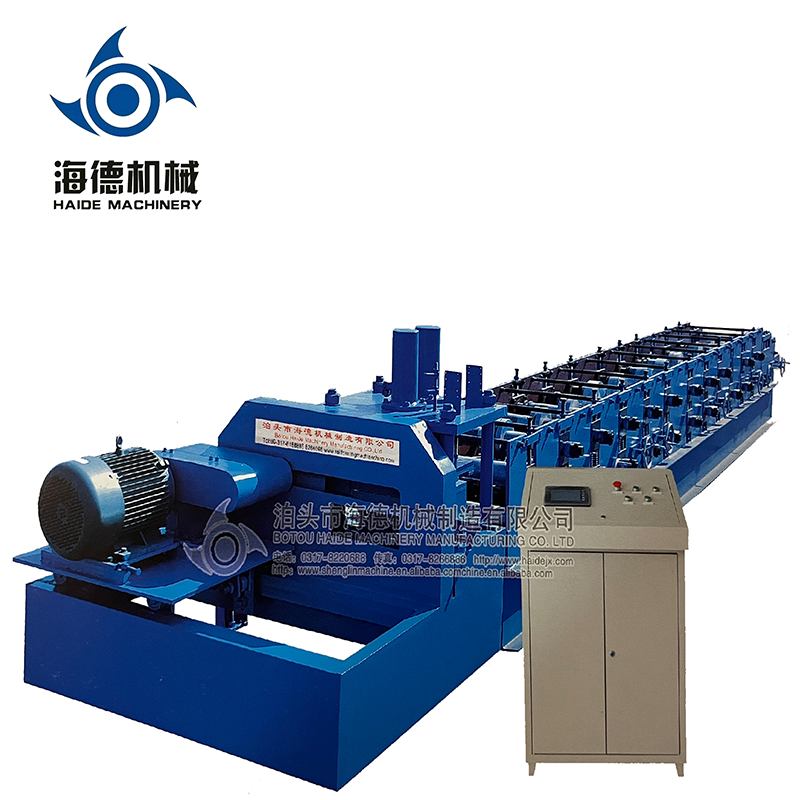

C-type steel purlin machine is a kind of efficient and intelligent equipment, mainly used for the production of various specifications of steel structure. It is characterized by high efficiency, energy saving and environmental protection, which provides a new production method for the construction industry.

It is efficient and environmentally friendly

It can greatly improve the production efficiency of the construction industry, reduce production costs, and ensure the quality and accuracy of products. In addition, the equipment also has good stability and durability, and can meet the production needs in a variety of complex environments.

It's a kind of purlin material with a special shape

Its cross section is Z-shaped, and it has a certain robustness and load-bearing capacity. Compared with the traditional straight line, type Z purlins can provide better support effect and play a stronger role in some special environments.

The metallic materials has steel, aluminum alloy and so on

These materials have excellent mechanical properties to withstand greater pressure and tension, and have good corrosion resistance and weathering resistance.

Different type of purlin machine

80/300 hydraulic drive z purlin roll forming machine

Z-shaped steel is mainly used for steel structure construction purlins, especially for large slope roof purlins. Widely used in railway vehicles, building doors and Windows, shelves, electrical cabinets, highway guardrail, containers, keel steel, municipal construction and other fields. And its specification size can be adjusted, but the adjustment is a range, to meet its specifications.

Hydraulic torsion c purlin roll forming machine

The appearance of C-type steel purlin machine has brought new opportunities and challenges to the modern construction industry.

Its characteristics of high efficiency, intelligence, environmental protection and energy saving will become an important development direction of the future construction industry.

80/300 c purlin forming machine

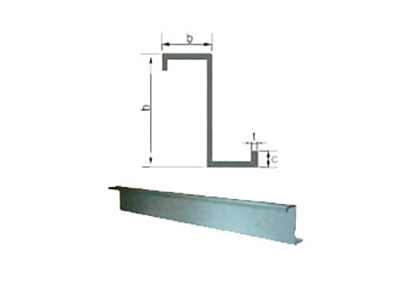

The texture of C-type purlin is very stable, with very good pressure resistance, even if it bears a very heavy external force, it will not affect the flatness of the purlin;

Hydraulic motor drives C-type steel purlin forming machine

The use of automatic control software to achieve production information management,the entire unit automation control system with a highly integrated network, so that the automation system performance is superior.

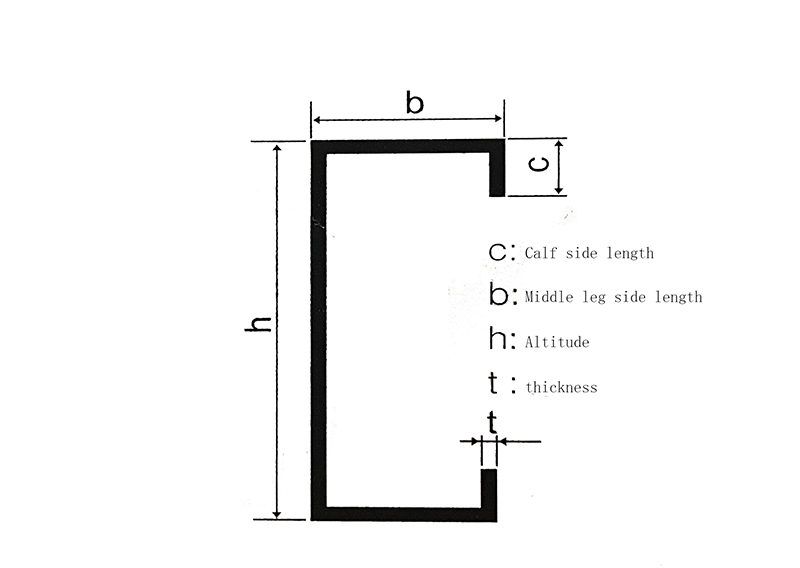

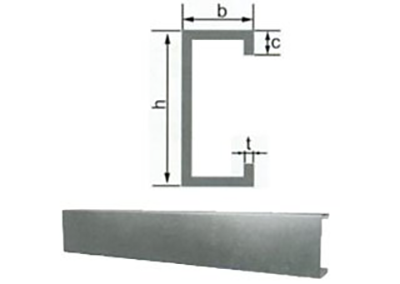

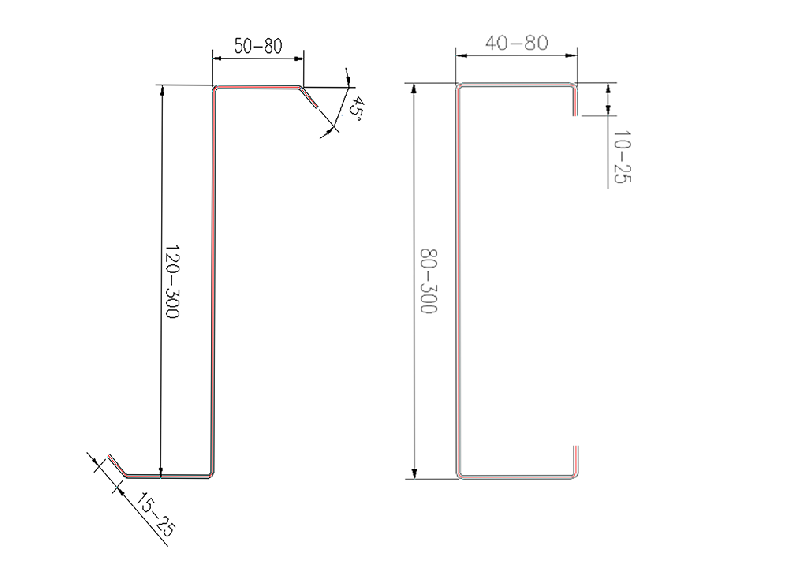

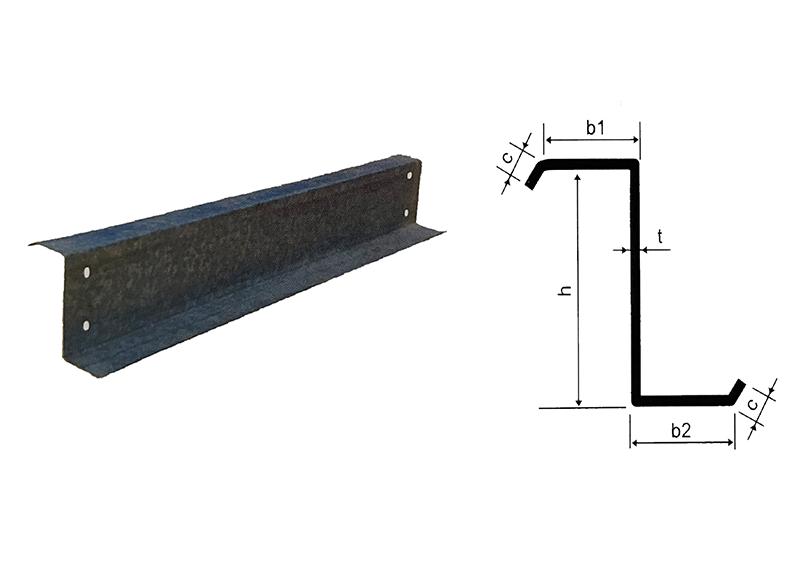

cz type keel purlin drawing and product

Botou Haide Machinery Manufacturing Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc.

FAQ

24 months from the date of loading by the seller, during the warranty period, we provide lifetime free technical support and repair consultation.

We have indoor and outdoor production workshops, which are real processing and production plants, including roller processing workshops, assembly workshops, spraying workshops and so on.