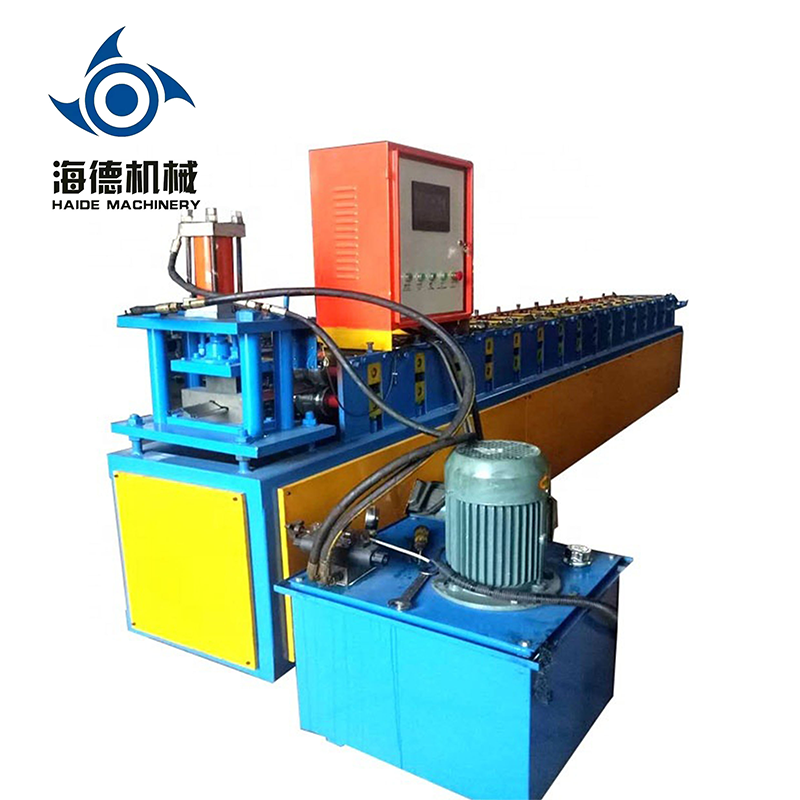

Roller shutter machine Supplier & Manufacturer

What is shutter door roll forming machine?

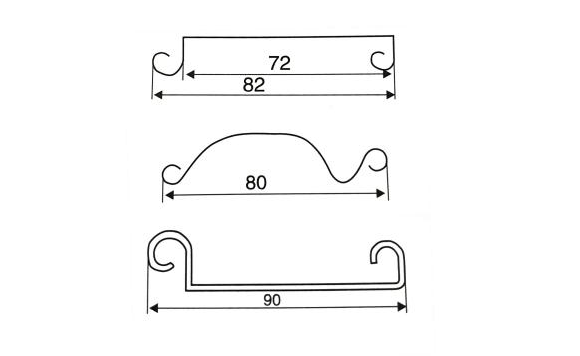

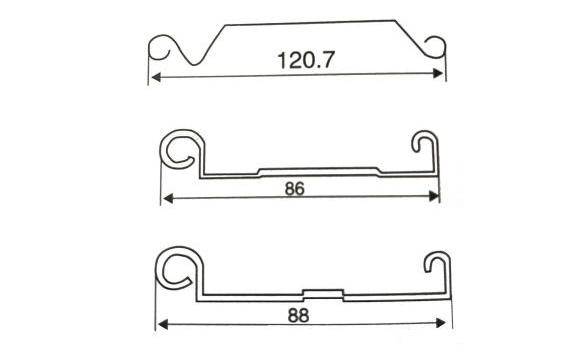

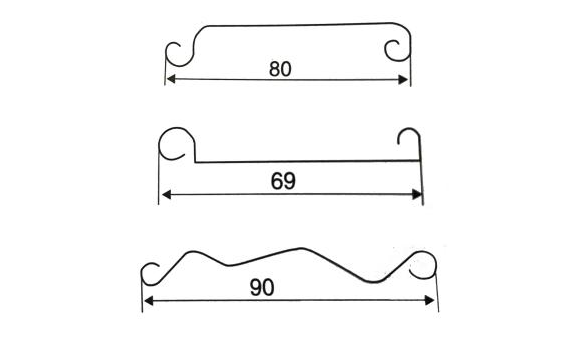

Rolling shutter door forming machinery refers to a mechanical equipment used for the production of rolling shutter doors. Its basic structure includes upper and lower roller shaft, side vertical plate, main shaft, guide wheel, transmission mechanism and so on. Rolling shutter molding machinery can produce a variety of different specifications, different shapes of rolling shutter doors, suitable for a variety of different occasions.

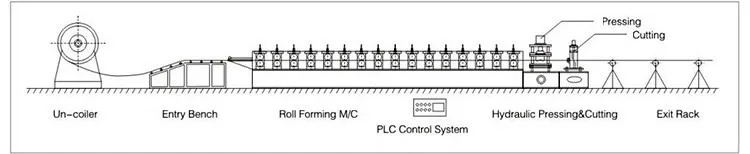

Working Flow of roller shutter door roll forming machine

Uncoiling – Sheet guiding – Roll forming – Length measurement – Pressure Mode – Cutting – Sheet to product support

Product Description | |

Name | Rolling shutter door forming machine |

Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

Thickness Range | 0.3-0.8 mm |

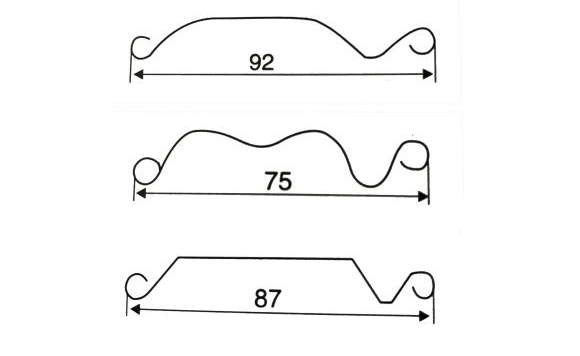

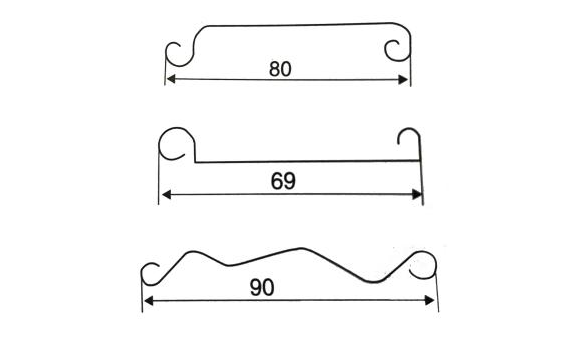

Coil Width Range | 90 95 100 105 130 mm. According to your actual drawing.

|

Cutting type | Automatic Hydraulic Cutting |

Main structure | 350H steel |

Roller material | Cr 12 |

Raw material | PPGI PPGI GI GL |

Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm. |

Characteristics of roller shutter door forming machine

Rolling shutter molding machinery is widely used in rolling shutter door manufacturing, which can be used to produce various types of rolling shutter doors in industry, commerce, agriculture, and home.

Rolling shutter molding machinery can adapt to different production environments according to specific needs, and produce rolling shutter doors of different materials, such as plastic rolling shutter doors, aluminum alloy rolling shutter doors, etc.

Rolling shutter door molding machinery can also produce a variety of fire, anti-theft, sound insulation and other functions of rolling shutter doors to meet the needs of the construction industry.

Aluminum alloy rolling shutter door produced by rolling shutter door forming machinery has the characteristics of high strength, corrosion resistance, and not easy to deform, and has been widely used in aerospace industry.

It is a kind of high efficiency mechanical equipment, suitable for tile production in industrial production, building tile processing and other fields.

It has the characteristics of high efficiency, high precision and high speed, and can quickly complete various processing tasks, which greatly improves the production efficiency

Factory Introduction

Our company specializes in the production of all kinds of cold rolling molding equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, etc.

FAQ

Since our machines are all customized products, please consult your salesman when placing an order.

We have indoor and outdoor production workshops, which are real processing and production plants, including roller processing workshops, assembly workshops, spraying workshops and so on.

24 months from the date of loading by the seller, during the warranty period, we provide lifetime free technical support and repair consultation.