Different types of CZ steel machines

C-shaped steel machine

Z-shaped steel machine

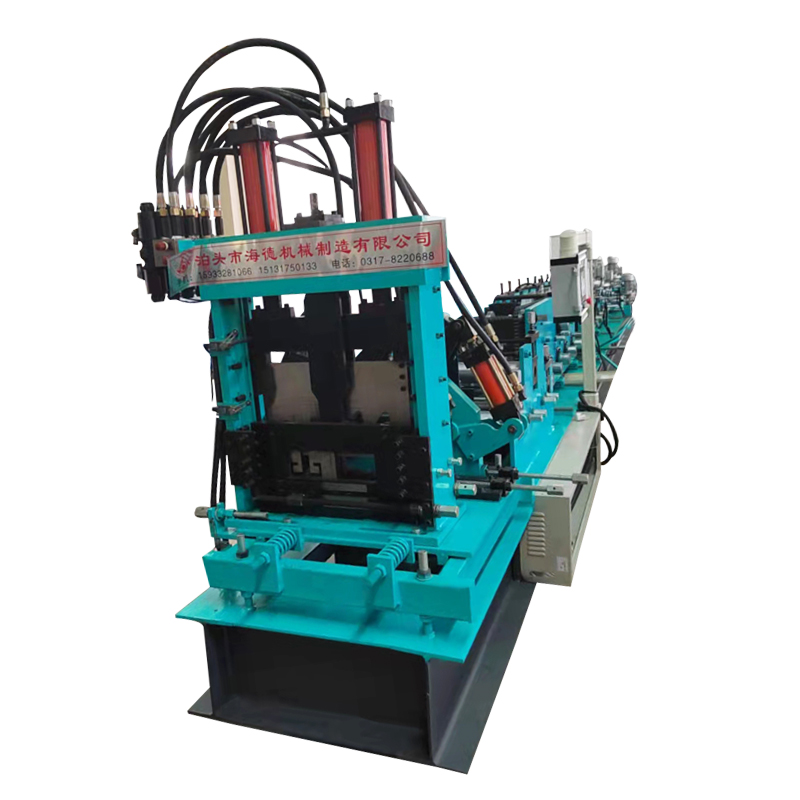

CZ integrated changeover machine

What is a C-shaped steel machine?

A C-shaped steel machine is a specialized equipment used for producing C-shaped steel. C-shaped steel is named after its cross-sectional shape resembling the English letter “C”. It is an efficient and economical cutting profile with characteristics such as light weight, high strength, and strong applicability.

What is a Z-shaped steel machine?

The Z-shaped steel machine is mainly used to produce Z-shaped steel (Z-shaped purlins), which is named after its cross-sectional shape resembling the English letter “Z”. Z-shaped steel has good bending resistance and is commonly used as a supporting component in building structures, especially in light steel structures.

What is CZ integrated changeover machine?

The CZ integrated changeover machine is an efficient automation equipment specifically designed for producing C-type and Z-type steel components. This machine can quickly switch between producing C-type and Z-type steel components without replacing the forming rollers through simple operation, greatly improving production efficiency and flexibility while reducing production costs.

The function of CZ integrated changeover machine

The function of CZ integrated changeover machine:

1. Improve production efficiency

-Quick changeover: It can complete the changeover from C-shaped steel to Z-shaped steel in a few minutes without stopping the machine to replace the forming rollers, greatly reducing the changeover time.

-Automated production: From the import of raw materials, forming, punching, cutting to the final output of finished products, the entire process has been automated, reducing manual intervention and improving production efficiency.

2. Reduce costs

-Reduce equipment investment: One CZ integrated changeover machine can replace multiple single function devices, reducing the cost of equipment procurement and maintenance.

-Reduce labor costs: Automated production reduces reliance on labor and lowers labor costs.

3. Improve product quality

-High precision: Adopting advanced control systems and precise machining processes to ensure the dimensional accuracy and surface quality of products, reducing scrap rates.

-Consistency: Automated production ensures consistent quality and specifications of each product, improving product reliability.

4. Enhance flexibility

-Multifunctionality: Able to produce multiple specifications of C-type and Z-type steel components on the same device, meeting the diverse needs of different customers and projects.

-Strong adaptability: It can handle steel plates of different thicknesses and materials, suitable for various construction and industrial fields.

5. Enhance security

-Security Protection : Equipped with multiple security protection measures and fault detection functions, ensuring the safety and stability of equipment operation and reducing the occurrence of safety accidents.

6. Energy conservation and environmental protection

-Efficient and energy-saving: adopting efficient motors and optimized designs to reduce energy consumption and meet the environmental protection requirements of modern industry.

-High material utilization rate: Automated production reduces material waste and improves material utilization rate.

7. Wide applicability

-Construction industry: used to produce components such as purlins, wall beams, etc. in steel structure buildings.

-Industrial field: used for making support structures, frames, etc. in various industrial equipment.

-Infrastructure construction: Steel structural components used in infrastructure such as bridges, railways, and highways.

8. Enhance competitiveness

-Quick response to the market: able to quickly adjust production plans, meet market demand in a timely manner, and enhance the market competitiveness of the enterprise.

-Improving customer satisfaction: High quality and efficient production can better meet customer needs, enhance customer satisfaction and loyalty.