Beginner’s Guide to Setting Up and Operating a Roof Tile Making Machine

Introduction

Roof tile manufacturing machine not only improves production efficiency and product quality, but also promotes the progress of building materials and technology, which is of great significance to meet the efficient, environmentally friendly and diversified needs of the modern construction industry.

Article purpose: To help beginners understand how to properly install and operate a roof tile making machine

How to choose the roof tile making machine

Choose the roof tile forming machine you need to consider the following aspects:

Production volume

Consider your own production needs to choose the right production speed of the machine. Different production machine configurations have different production speeds.

| fast | Servo motor | $ 25000 |

| High speed | Hydraulic motor | $ 12000 |

| Low speed | Planetary cycloid | $ 8000 |

Type of tile

The first choice is to determine the cold forming equipment you need to produce

Color steel tile machine is mainly applied to what raw materials

Color steel plate aluminum plate than tin plate nano plate rubber plastic cotton stainless steel, etc.

Quality and durability

Color steel tile is widely used in the construction industry because of its light weight, high strength, beautiful appearance, thermal insulation and easy installation, especially in industrial plants, warehouses, temporary buildings, rural housing and other projects. By selecting the right thickness, high-quality coating, reasonable installation and proper maintenance, color steel tiles can show excellent durability and long-term economic benefits.

Maintenance requirements

The maintenance cost of color steel tile is reasonable relative to its durability and maintenance cycle, and the daily maintenance work is relatively simple, which can effectively extend its service life and maintain a good appearance. For the parts that require professional maintenance, although the cost and complexity are higher, considering the overall performance and replacement costs of color steel tiles, regular professional maintenance is a necessary investment.

Safety standards

Compliance with local and international production safety standards has been ensured.

The machines are produced in accordance with local environmental requirements.

Roof tile Machine Installation Guide

Venue selection

Choose a flat and relatively spacious place to place the roof tile machine.

Machine assembly

Machine Operation Guide

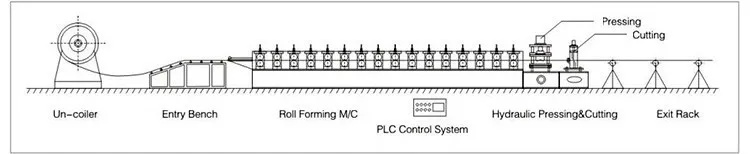

The tile press is a special equipment for the production of various tiles, and its components mainly include the fuselage, the press roll, the pressing die and the control system.

Preparation before use

Power supply preparation:

Ensure that the power supply meets requirements, and connect the ground cable to ensure power stability.

Lubrication and inspection:

Check whether the oil circuit is smooth, and add enough lubricating oil.

Check whether the parts of the tile press are in good condition and whether there are abnormal conditions such as loosening.

Mold preparation:

Install the appropriate mold as required, and adjust the height and width of the roller.

Material preparation:

Prepare the tile material to be processed and place it on the work table of the tile press.

Operation steps

Boot and preheat:

Turn on the power switch and preheat the equipment according to the type and specifications of the tile press.

Parameter setting:

According to the tile material and size, set the appropriate processing parameters, including pressure, speed, etc.

Debugging and loading:

Debug the machine to ensure that the tool height, deviation Angle and other parameters meet the requirements.

Load the tile design pattern to be processed into the control system of the tile press, and set the corresponding program.

Start processing:

According to the set program, start the automatic operation mode, so that the tile press can process according to the preset pattern and parameters.

Process monitoring:

Observe the processing process of the tile press, check the quality and processing effect of the tile, and ensure the accuracy and consistency of the processing.

Finish processing:

After the processing is completed, stop the automatic operation mode of the tile press, disassemble the processed tiles, and prepare the next batch of processing.

Precautions

Safe operation:

Pay attention to safety during operation to avoid injuries to hands or other body parts.

Do not exceed the maximum processing capacity specified by the equipment, otherwise it may damage the equipment or cause safety accidents.

Material requirements:

Ensure that the size of the processed material meets the requirements, and avoid excessive length or width of the material caused by danger.

Maintenance:

Regularly check whether all parts of the equipment are in normal operation, and carry out necessary maintenance.

Common faults and treatment methods

(This may vary according to the device model and brand. You are advised to refer to the device manual.)

Power failure:

Check whether the power connection is secure and the power switch is normal.

Mold damage:

Stop the equipment, replace the new mold, and check whether the mold is firmly installed.

Processing effect is not ideal:

Check whether the parameter Settings are correct, adjust the parameters, and then re-process.

Problems that may be encountered during production

Equipment failure and performance problems

Electrical failure: such as power line failure, motor failure, electrical component damage, etc., may cause the tile press can not start or run unstable.

Mechanical failure: such as transmission component damage, bearing wear, gear fracture, etc., may lead to poor operation of the equipment or produce abnormal noise.

Control system problems: The failure of the control system may cause the equipment to fail to operate according to the preset program, affecting the production quality and efficiency of the tile.

Second, the production accuracy problem

Mold accuracy problem: The accuracy of the mold directly affects the forming quality of the tile, such as mold wear or unreasonable design, may lead to tile size instability, irregular shape and other problems.

Improper adjustment: The upper and lower mold alignment of the equipment is not accurate, or the pressure adjustment is not appropriate, which may lead to the tile pressing is not firm, resulting in deviation and other problems.

Third, raw materials

Unstable material quality: The quality of raw materials directly affects the performance and service life of tiles, such as the use of low-quality raw materials may lead to tile surface uneven, easy to damage and other problems.

Insufficient supply of materials: Unstable supply of raw materials can lead to production disruptions, affecting production efficiency and delivery times.

Maintenance and maintenance issues

Lack of routine maintenance: Lack of routine maintenance of equipment can lead to performance degradation and frequent failures, affecting production efficiency and equipment life.

Improper maintenance: Improper maintenance may aggravate the wear and damage of the equipment, and even lead to the abandonment of the equipment.

Operational problems

Improper operation: The operator does not follow the operation rules, which may cause equipment damage and safety accidents.

Unlicensed: Untrained operators may lack the necessary skills and knowledge, leading to various problems in the production process.