780 Glazed Tile Roll Forming Machine Supplier & Manufacturer

Type-780 glazed tile roll forming machine

Customize your own glazed tile roof roller forming machine

The type 780 is the one of glazed tile machine , The molding width of the glazed plate is 780cm .

- Whatsapp:+86 19833726222

- Email:admin@haidejx.com

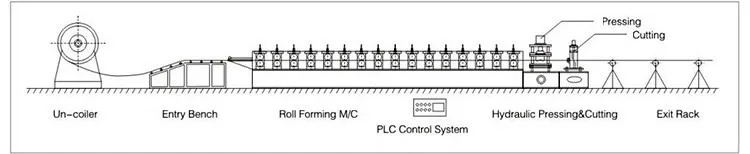

In roll forming, metal sheets are passed through a series of rollers, gradually shaping them into the desired profile. This process allows for high precision and efficiency in mass-producing tiles. Glazed tile roll forming machines typically include components for decoiling, guiding, forming, cutting, and stacking the finished tiles.

780 technical parameters of glazed tile forming machine

weight | 3500kg |

dimension | 9.6m* 1.5m* 1.3m |

Color | According to customer demand |

Ingredients | PPGI PPGL GI GL |

thickness | 0.3-0.8MM |

Coil width | According to customer demand |

Apply | Building construction |

Cutting type | Fully automatic hydraulic cutting |

Main frame | 350H steel |

Motor power | 5.5kw |

Hydraulic pump power | 3kw |

productivity | 15-20M/Min |

Roller material | 45# |

Our 780 version is mainly 1000mm in width and 32mm in peak height. You can also provide me with the picture of the version you need, and our machine can be customized according to your needs.

Work flow of glass roof tile pressing machine

Uncoiling — Sheet guiding — Roll forming — Measure length — Pressure pattern — Cutting — Panels to product stand

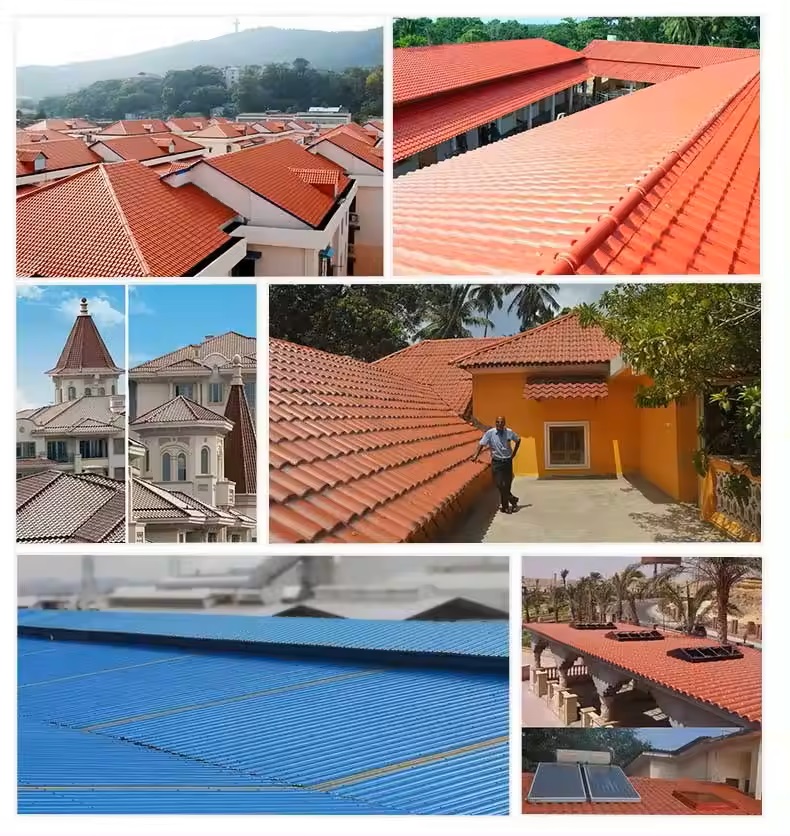

All type of roof tile

What are the parts of the machine

- Raw material feeding system

- Main forming frame

- Servo drive system

- Hydraulic system

- Cut-off device

- Electronic control system

- Lubrication cooling system

- Finished product delivery system

Advantage

1. Excellent physical properties: glazed tile is usually made of high quality ore raw materials, through high pressure molding and high temperature firing, so high strength, bending resistance, frost resistance, acid and alkali resistance, with good durability and stability.

2. Good water resistance: whether it is traditional or western glazed tile, it emphasizes the waterproof performance of its surface glaze layer, which can effectively prevent water penetration, and is suitable for various climatic conditions, especially for roof building materials, to ensure that buildings are not corroded by rain.

3. Beautiful and decorative: rich glazed tile, delicate texture, bright colors or rustic, can add classical or modern beauty to the building, often used to create a specific architectural style, such as Chinese, European and so on.