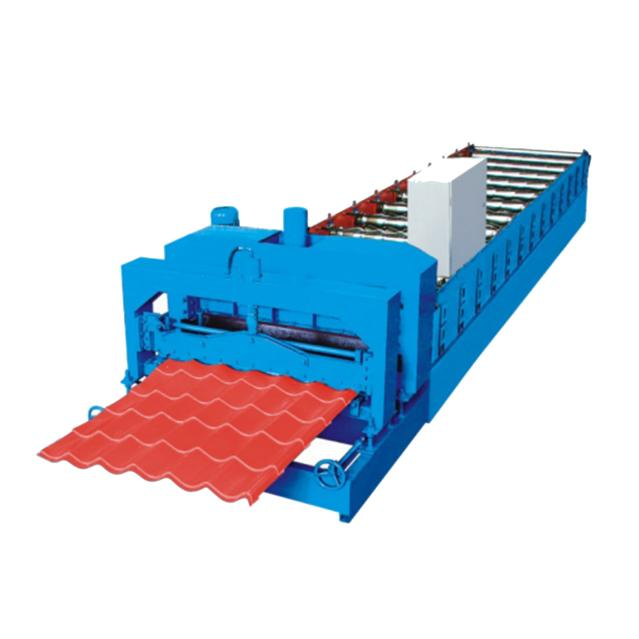

Glazed Tile Roll Forming Machine Supplier & Manufacturer

What is glazed tile roll forming machine?

The glazed tile machine is an efficient and environmentally friendly mechanical equipment for producing glazed tiles. It integrates the advantages of modern machinery and intelligent control technology, making the produced glazed tiles not only aesthetically pleasing but also highly practical.The Panels made by our Roll Forming Machine have beautiful appearance and bright color.

The production line uses galvanized steel plates or colored steel plates or aluminum plates of different colors as raw materials. The products produced are used for building exterior roof and wall panels, as well as interior decorative panels or ceilings, to enhance the aesthetics and durability of the roof or walls.water penetration. The water absorption rate on the back side meets the national.

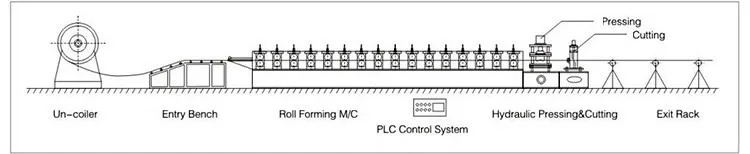

Working flow of glazed tile machine

Uncoiling — Sheet guiding — Roll forming — Measure length — Pressure pattern — Cutting — Panels to product stand

| Product Description | |

| Name | Galzed floor color coated tile making machine sheet machinery |

| Suitable Material | Colored or galvanized steel coil, HRB60 or equivalent |

| Thickness Range | 0.3-0.8 mm |

| Coil Width Range | 914, 1000, 1220 or 1250 mm. According to your actual drawing. |

| Electric Powe | 380V, 50 Hz, 3 phase or according to your need. |

| Dimension | About 7.2*1.3*1.1m(L*W*H), as per the drawing |

| Cutting | Automatically stop and cutting when it comes to the set length. |

| Length of the Sheet | You can set the length according to your need. It is controlled by PLC length accuracy: ±1mm. |

| Raw material | PPGI PPGI GI GL |

| PLC | detla |

| Cutting blade material | Cr12Mov |

Feature of glazed sheet roll forming machine

Beautiful appearance:

The variety of colors of glazed tiles can make the roof more layered.

High strength:

The surface of the glazed tile is coated with a glossy glaze layer, which is non permeable and does not accumulate water.

Low water absorption:

Glass tiles will not cause cracking due to thermal expansion and contraction, and can maintain color stability even under long-term exposure to sunlight.

High degree of automation

The degree of machine automation is high, reducing manual intervention and labor intensity.

More type of roof sheet panel

Another type of glazed roll forming machine

Featuring rich and colorful colors and unique patterns, it can provide unique decorative effects for buildings.

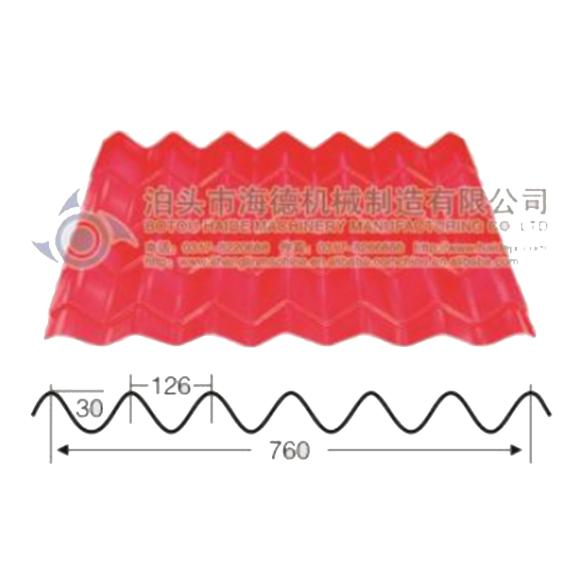

Type 780 arc glazed tile making machine

It has good durability and can maintain a long-term service life under normal usage conditions, and is not easily affected by oxidation,

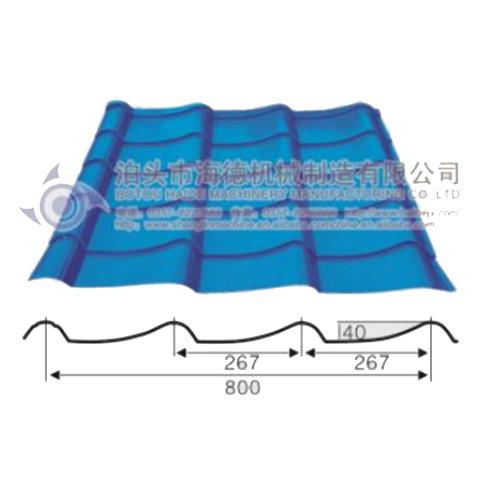

Type 800 bamboo glazed sheet roof machine

It does not release toxic gases during combustion and has good fire resistance, which can improve the safety of buildings.

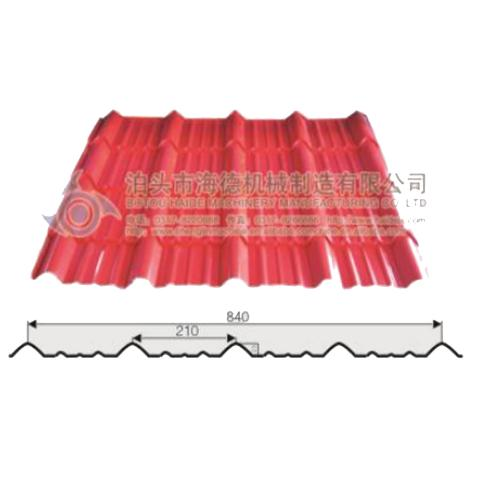

840 arc glazed tile pressing equipment

Glazed tile making machine has good waterproof performance and can effectively prevent rainwater leakage.

Type 830 arc glazed tile roof machine

Tiles have certain thermal insulation properties, which can improve the insulation performance of buildings and reduce energy consumption.

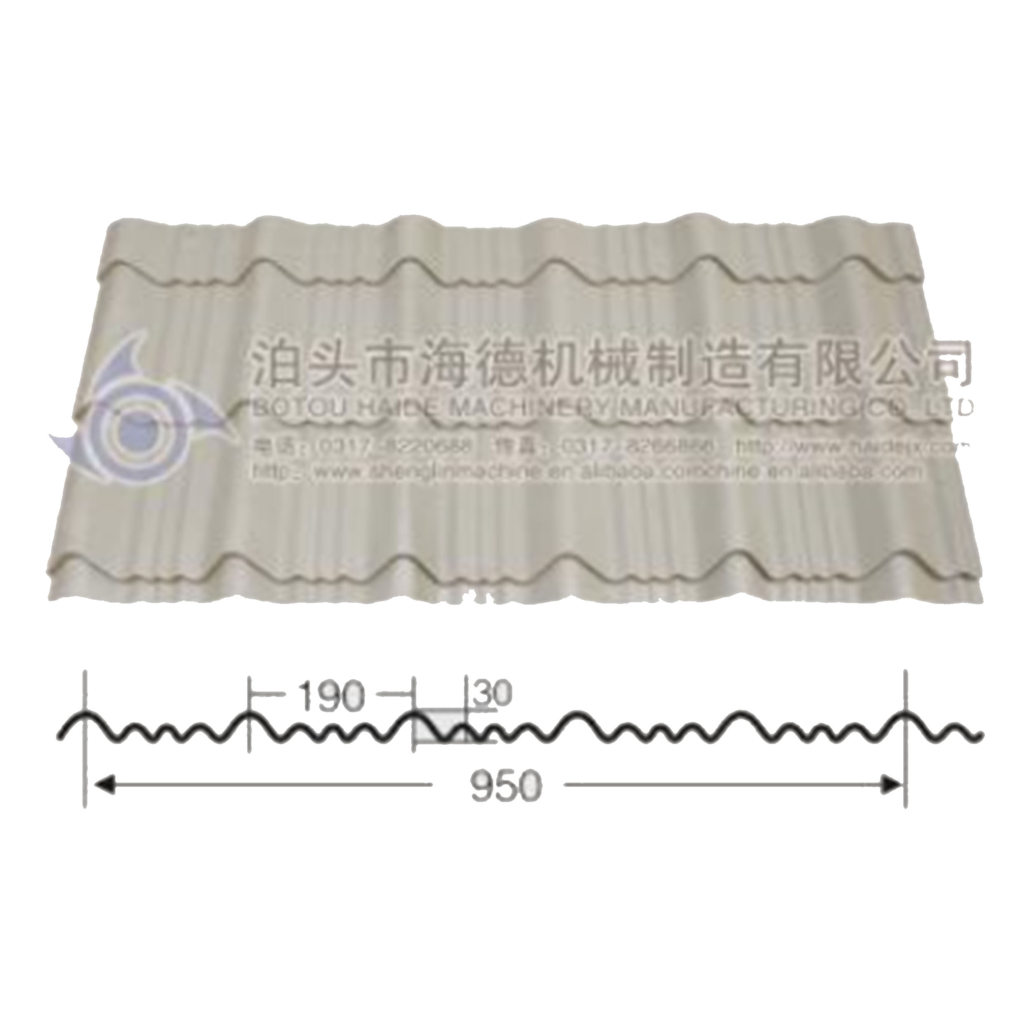

Type 960 arc glazed sheet roll forming machine

It is a natural material that does not contain harmful substances, has no pollution to the environment, and meets environmental

780 glazed tile profiling equipment

The installation is relatively simple, the construction cost is low, and labor and material costs are saved.

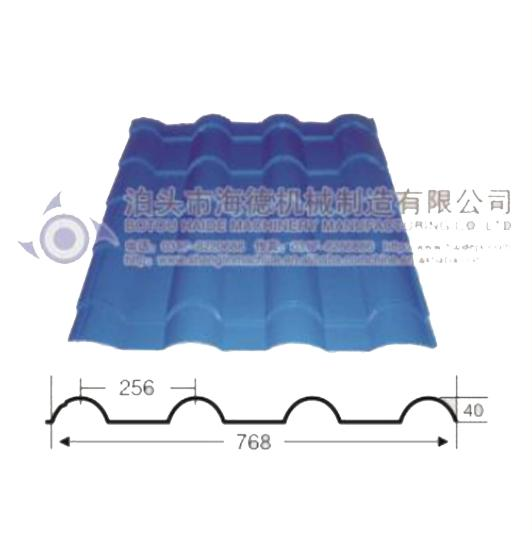

Type 768 glazed tile sheet equipmeng

It has a high degree of resistance to moisture and alkali, and can be used in relatively humid and alkaline environments.

Glazed tile can be used as roof covering can make the surface temperature of the roof than the surface temperature of conventional stone, cement and other roof materials Reduce by about 8-10 degrees Celsius.

Factory Introduction

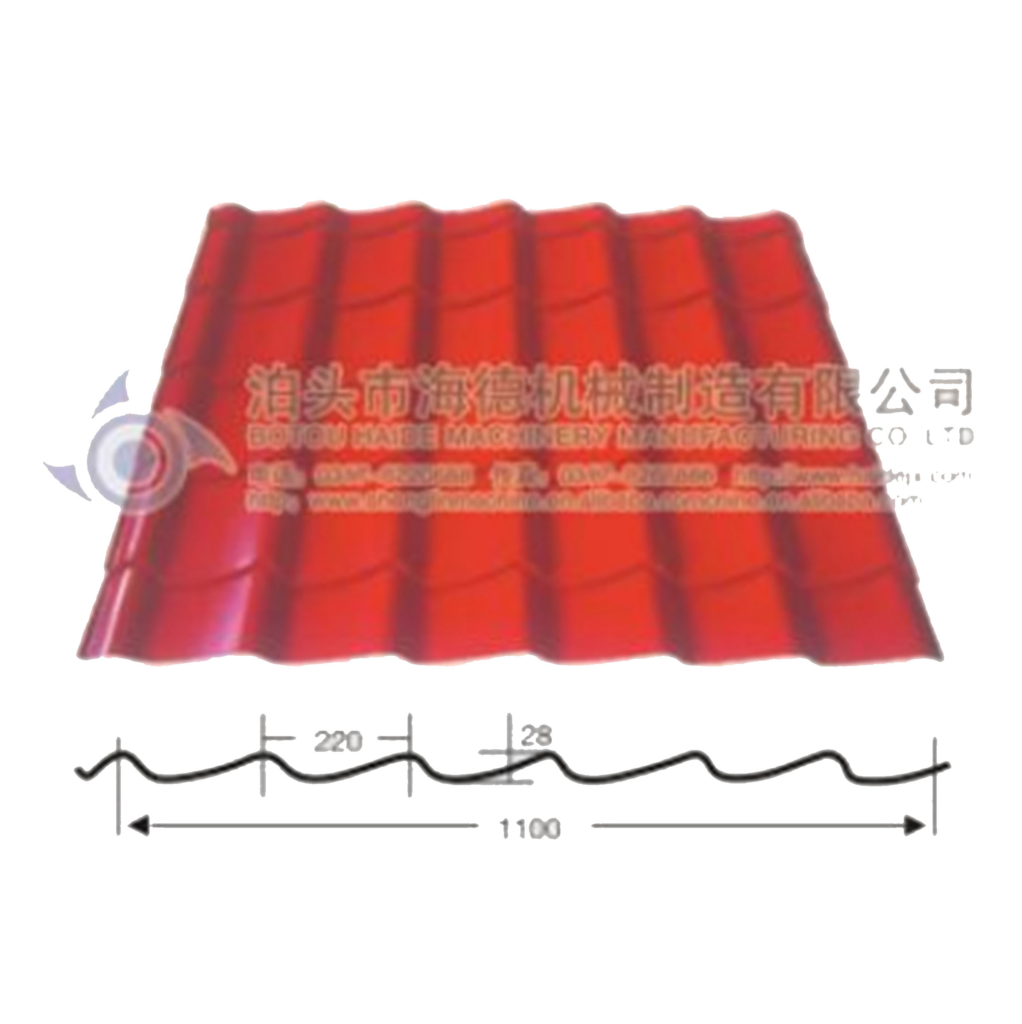

Our company specializes in producing various types of cold rolling forming equipment. With 20 years of production and export experience, our export countries cover Bosnia and Herzegovina, Bolivia, the United States, Germany, Mozambique, Namibia, and more. The glazed tiles produced by our company are divided into 828, 820, 800, 840, 830, 720, 780, 768, and 1100 molding equipment.

FAQ

Yes sir/ Madam.

If you don’t have profile drawings, the solutions have:

1.1 : Provide me with your profiles’ pictures ;

1.2 : Tell me your country and i will check if we sell similar / related profile machines to your there. I will recommend you related profile drawings.

1.3 : Tell me any information you have and it will be helpful for me to clear your needed profiles. and then quote you.

Yes sir/Madam.

We will do the machine according to your profile drawing . About the profile drawing, we will confirm with you again before producing your machine. Then, after the machine finished, we will test the machine and guarantee the machine you received is a good machine. Because after you satisfied with the machine, and then you pay balance.

One machine is okay.